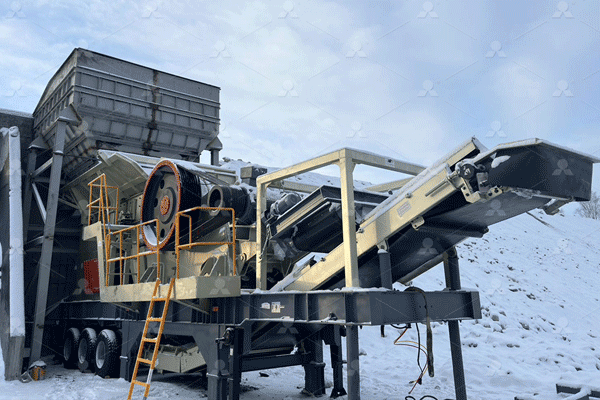

Construction Waste Mobile Jaw Crusher for Sale

Introduction

Construction waste management has become a critical issue in modern urban development. With increasing demolition and renovation projects, the need for efficient recycling solutions is growing. A mobile jaw crusher designed specifically for construction waste offers flexibility, efficiency, and environmental benefits. These machines crush concrete, bricks, asphalt, and other debris into reusable aggregates, reducing landfill dependency and lowering costs. This article explores the advantages, working principles, applications, and purchasing considerations of mobile jaw crushers for construction waste recycling.

Advantages of Mobile Jaw Crushers

Mobile jaw crushers provide several key benefits for construction waste processing. First, their portability allows on-site crushing, eliminating transportation costs and reducing carbon emissions. Second, they offer high efficiency—modern models crush large volumes quickly with adjustable output sizes. Third, they enhance sustainability by converting waste into reusable materials like gravel or base layers for new construction. Additionally, these machines require minimal setup time and can operate in confined spaces due to their compact design. Compared to stationary crushers, mobile units significantly improve workflow adaptability on dynamic job sites.

How It Works

A mobile jaw crusher operates using compressive force to break down materials. The machine consists of a vibrating feeder that directs debris into the crushing chamber where two metal plates—the fixed jaw and the moving jaw—apply pressure to fragment the waste. Crushed material exits through an adjustable discharge gap that controls particle size. Advanced models include screening systems to separate fine aggregates from larger pieces automatically. Hydraulic systems enable quick adjustments while diesel-electric or hybrid power options ensure fuel efficiency in remote locations without electricity access.

Applications in Construction Waste Recycling

These crushers are ideal for various recycling tasks such as processing demolished concrete structures or asphalt roads into usable fill material or road base layers.They also handle mixed debris containing rebar or wood fragments when equipped with magnetic separators or sorting belts.Mobile jaw crushers are commonly used in urban redevelopment projects where space constraints demand compact equipment.Infrastructure upgrades like highway repairs benefit from immediate aggregate production at demolition sites rather than hauling raw materials from distant quarries.This reduces project timelines while promoting circular economy practices within the industry.

Key Features When Purchasing

When selecting a mobile jaw crusher,focus on crushing capacity,mobility,and durability.High-capacity models process more tons per hour but may require stronger power sources.Optimize mobility based on terrain—track-mounted units perform better on rough ground while wheeled versions suit paved areas.Durability depends on wear-resistant components like manganese steel jaws.Check maintenance accessibility since frequent servicing extends machine life.Some manufacturers offer remote monitoring systems that track performance metrics digitally.Finally,evaluate fuel consumption rates alongside operational costs before finalizing your purchase decision.

Conclusion

Investing in a mobile jaw crusher tailored for construction waste presents long-term economic and ecological advantages.Its ability to recycle materials onsite cuts expenses while supporting sustainable building practices.With advancements improving efficiency,ease-of-use,and adaptability across different environments,the demand will continue rising globally.Selecting the right model requires balancing technical specifications with real-world project needs,but doing so ensures maximum return-on-investment over time.As regulations tighten around landfill usage,mobile crushing solutions become indispensable tools transforming demolition byproducts into valuable resources efficiently