Factory Price Ethiopia Mine 200-300tph Automatic Crusher: A Smart Investment

Introduction to Automatic Crushers

Automatic crushers have revolutionized the mining and construction industries by improving efficiency and reducing labor costs. These machines are designed to handle large volumes of raw materials, such as rocks and ores, with minimal human intervention. In Ethiopia, where mining operations are expanding rapidly, a 200-300tph (tons per hour) automatic crusher offers a reliable solution for processing bulk materials efficiently.

The key advantage of automation lies in its precision and consistency. Unlike manual crushing methods, automatic crushers ensure uniform output sizes, which are crucial for downstream processing. Additionally, they reduce operational risks by minimizing direct worker exposure to hazardous conditions.

Why Choose a 200-300tph Capacity?

A crusher with a capacity of 200-300tph strikes the perfect balance between power and practicality for medium to large-scale mining operations. This range is ideal for Ethiopian mines that require steady production without overburdening energy resources or maintenance schedules.

Higher-capacity machines often come with increased operational costs, while smaller units may not meet production demands. The 200-300tph range ensures optimal throughput while keeping fuel consumption and wear-and-tear manageable. For mines aiming to scale up gradually, this capacity provides room for growth without requiring immediate upgrades.

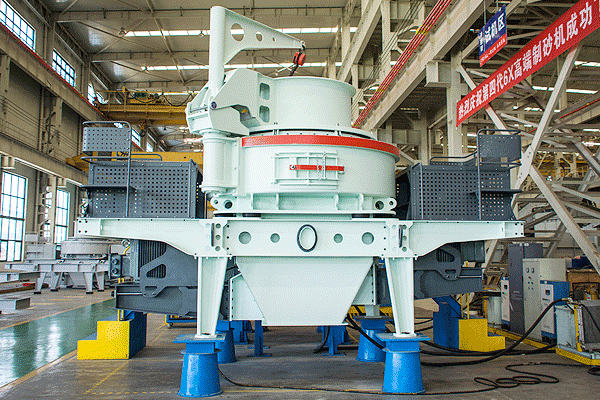

Key Features of Factory-Priced Models

Factory-priced automatic crushers offer affordability without compromising essential features. Some notable functionalities include:

- Advanced Control Systems: User-friendly interfaces allow operators to adjust settings effortlessly.

- Durable Construction: High-quality materials extend the machine’s lifespan even in harsh environments.

- Energy Efficiency: Modern designs minimize power consumption while maximizing output.

These models eliminate unnecessary add-ons that inflate costs, making them accessible for budget-conscious buyers without sacrificing reliability or performance.

Applications in Ethiopian Mining

Ethiopia’s mining sector primarily focuses on gold, tantalum, and gemstones, all of which require efficient crushing solutions before further processing. An automatic crusher simplifies extraction by breaking down large rocks into manageable fragments quickly and consistently.

Moreover, these machines support infrastructure development projects by providing crushed aggregates for road construction and building materials production—a growing need in Ethiopia’s urban expansion efforts. Their versatility makes them indispensable across multiple industries beyond traditional mining applications alone!

Cost-Effectiveness & Long-Term Benefits

Investing in factory-priced equipment significantly reduces upfront expenses compared to premium brands offering similar specifications—without compromising core functionalities like automation or durability! Over time lower maintenance requirements translate into additional savings too since fewer breakdowns mean reduced downtime expenses overall…

Furthermore automated systems enhance safety standards by reducing manual handling risks associated with traditional methods—protecting workers while boosting productivity simultaneously! For Ethiopian miners seeking sustainable growth opportunities investing wisely now ensures profitability later down line when demand increases further still…

By choosing wisely today operators secure competitive advantages tomorrow through smarter technology adoption at accessible price points tailored specifically towards emerging markets just like theirs here locally within region itself where every dollar counts most importantly perhaps above all else? That said careful research remains vital before committing purchase decisions fully though naturally so always consult experts beforehand whenever possible too!