Gold Ore Crusher Machine for Mining

Introduction to Gold Ore Crushing

Gold ore crushing is a crucial step in the mining process, transforming large chunks of raw ore into smaller, manageable pieces for further processing. A gold ore crusher machine plays a vital role in breaking down hard rock or alluvial deposits efficiently. These machines come in various types, each suited for different stages of crushing—primary, secondary, and tertiary. The choice of crusher depends on factors such as ore hardness, desired output size, and production capacity. Proper crushing ensures optimal mineral liberation, improving recovery rates during subsequent processing stages like milling and leaching.

Types of Gold Ore Crushers

Several crushers are commonly used in gold mining operations:

- Jaw Crushers: Ideal for primary crushing, these machines use compressive force to break large rocks into smaller fragments.

- Cone Crushers: Suitable for secondary and tertiary crushing, cone crushers offer finer particle sizes by squeezing material between a rotating mantle and concave liner.

- Impact Crushers: These utilize high-speed impact to shatter ore particles, making them effective for softer ores or recycling applications.

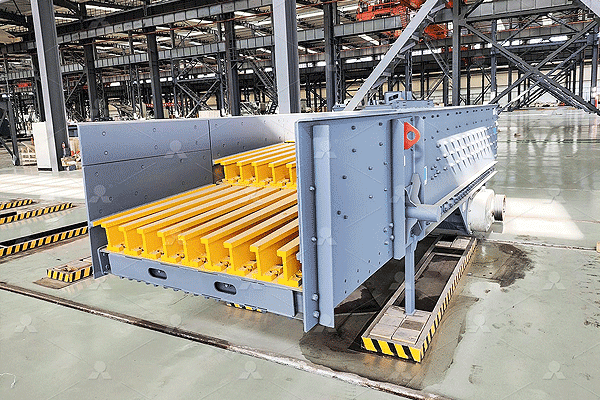

- Roll Crushers: Best suited for processing brittle materials with minimal fines generation.

Each type has advantages depending on the ore characteristics and processing requirements.

Key Features of an Efficient Crusher

A high-quality gold ore crusher should possess several essential features:

- Durability: Mining environments are harsh, so crushers must be built with wear-resistant materials like manganese steel or hardened alloys.

- Adjustable Settings: The ability to control output size ensures flexibility in meeting different processing needs.

- Low Maintenance Design: Easy access to critical components reduces downtime and operational costs.

- Energy Efficiency: Advanced designs minimize power consumption while maintaining high productivity levels.

Investing in reliable equipment improves long-term profitability by reducing breakdowns and maintenance expenses.

Maintenance Tips for Optimal Performance

Regular maintenance extends the lifespan of gold ore crushers while ensuring consistent performance:

- Lubricate moving parts frequently to prevent excessive wear caused by friction or heat buildup.

- Inspect liners periodically—worn-out liners reduce efficiency significantly.

- Monitor belt tension (if applicable) since loose belts can slip under heavy loads.

- Clean dust accumulation around bearings because contaminants accelerate component degradation.

Following manufacturer guidelines helps avoid unexpected failures that could disrupt production schedules severely.

Safety Considerations When Operating Crushers

Safety remains paramount when handling heavy machinery like gold ore crushers:

Operators must wear protective gear including helmets gloves safety glasses at all times during operation.

Never bypass safety interlocks designed prevent accidental startups while servicing equipment.

Ensure proper training before allowing personnel operate complex systems unsupervised.

Establish emergency shutdown procedures mitigate risks associated with mechanical failures quickly effectively.

Adhering strict protocols minimizes workplace accidents protecting both workers investments alike.

Conclusion

Choosing right type maintaining properly operated safe manner maximizes efficiency profitability within mining operations involving precious metals extraction from ores . Understanding key aspects selection usage ensures smooth workflow throughout entire mineral recovery chain ultimately leading higher yields lower operational costs over time . Whether dealing primary secondary tertiary stages having robust dependable system place makes significant difference overall success project .