How Big of a Rock Can a Jaw Crusher Crush?

Understanding Jaw Crusher Capacity

Jaw crushers are powerful machines designed to break down large rocks into smaller, more manageable pieces. The size of rock a jaw crusher can process depends on several factors, including the machine’s feed opening, crushing chamber design, and motor power. Generally, jaw crushers can handle rocks up to 48 inches in diameter, though some heavy-duty models may accept even larger materials. The key factor is ensuring that the rock fits within the feed opening without causing blockages or excessive wear on the crusher components.

Factors Affecting Crushing Performance

Several variables influence how effectively a jaw crusher processes large rocks:

- Feed Opening Size – Determines the maximum rock size that can enter the chamber.

- Crushing Force – Higher force allows harder or larger rocks to be crushed efficiently.

- Material Hardness – Softer rocks like limestone break easier than granite or basalt.

- Moisture Content – Wet or sticky materials may clog the crusher, reducing efficiency.

Properly matching the rock size to the crusher’s specifications ensures optimal performance and longevity of the machine.

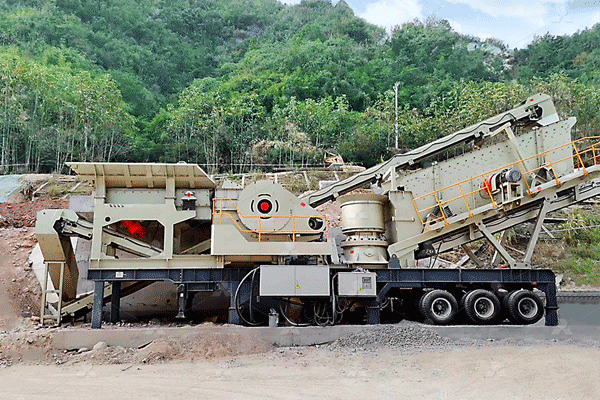

Common Applications for Large Rock Crushing

Jaw crushers are widely used in mining, quarrying, and construction industries where large rocks must be reduced for further processing. They excel at primary crushing—breaking down raw materials extracted from blast sites or natural deposits before secondary crushing stages. Some typical applications include:

- Processing oversized boulders in quarries

- Reducing demolition concrete debris

- Preparing raw ore for mineral extraction

Their robust design makes them ideal for handling tough materials efficiently.

Maintenance Tips for Optimal Performance

To ensure consistent crushing capacity and prevent breakdowns, regular maintenance is crucial:

- Inspect wear parts (jaws, liners) frequently and replace them when worn out.

- Keep the feed area clear of obstructions to avoid unnecessary strain on the motor.

- Lubricate moving parts as per manufacturer guidelines to reduce friction-related damage.

- Monitor vibration levels; excessive shaking may indicate misalignment or mechanical issues.

Proper upkeep maximizes efficiency and extends the lifespan of jaw crushers processing large rocks daily.

Conclusion: Choosing the Right Crusher for Your Needs

When selecting a jaw crusher for large rock processing, consider both immediate requirements and long-term operational demands. Assessing factors like material hardness, desired output size, and production volume helps determine whether standard or heavy-duty models are necessary—ensuring reliable performance while minimizing downtime due to improper sizing or wear-related failures over time!