Cost Analysis of a 100 TPH Mobile Jaw Crusher for Basalt Processing

Introduction

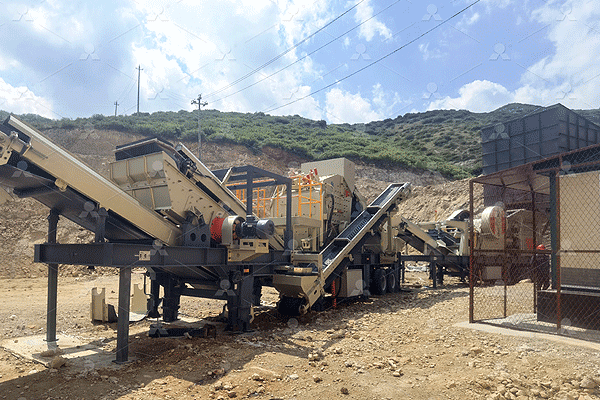

Mobile jaw crushers are essential equipment in modern quarrying and mining operations, particularly for processing hard materials like basalt. A 100-ton-per-hour (TPH) mobile jaw crusher offers flexibility, efficiency, and mobility, making it ideal for contractors and mining companies that require on-site crushing solutions. This article explores the factors influencing the cost of such equipment, its operational advantages, maintenance considerations, and market trends—without referencing specific brands or manufacturers.

Factors Affecting the Price

The cost of a 100 TPH mobile jaw crusher designed for basalt varies significantly based on several key factors:

- Production Capacity & Efficiency – Higher-capacity machines with optimized crushing chambers command premium prices due to their ability to handle tougher materials efficiently.

- Material Durability – Basalt is abrasive and hard, requiring wear-resistant components (e.g., manganese steel jaws), which increase manufacturing costs.

- Mobility Features – Track-mounted units with advanced hydraulic systems are more expensive than simpler trailer-based models but offer superior maneuverability.

- Automation & Technology – Models with remote monitoring, automated adjustments, and fuel-saving features tend to be priced higher due to their long-term operational benefits.

- Market Demand & Supply Chain – Global steel prices, shipping costs, and regional demand fluctuations can impact final pricing by 10–20%.

Prices typically range between $250,000 and $500,000 USD depending on these variables. Buyers should evaluate total lifecycle costs rather than just upfront expenses.

Operational Advantages

A 100 TPH mobile jaw crusher tailored for basalt provides distinct benefits:

- On-Site Processing – Eliminates transportation costs by crushing material directly at excavation sites or quarries.

- Versatility – Adjustable settings allow operators to produce different aggregate sizes suitable for construction or road-building applications.

- Fuel Efficiency – Modern diesel-electric hybrids reduce operating expenses compared to traditional purely diesel-powered units.

- Quick Setup Time – Modular designs enable rapid deployment without extensive foundation work required by stationary crushers.

These advantages justify the investment for businesses prioritizing productivity and cost-efficiency in medium-scale projects lasting several months or years.

Maintenance Considerations

Owning a mobile jaw crusher entails ongoing upkeep expenses critical for sustaining performance when processing abrasive basalt:

- Wear Parts Replacement – Jaws, liners, and blow bars degrade faster with hard rock; frequent inspections prevent unexpected downtime.

- Lubrication Systems – Automated greasing systems prolong bearing life but require periodic servicing.

- Engine & Hydraulics Maintenance – Regular oil changes filter replacements ensure optimal power transmission efficiency over time.

- Software Updates (if applicable) – Smart-connected models may need firmware upgrades periodically enhancing functionality safety protocols.

Proactive maintenance schedules can reduce repair bills by up-to-30% while extending equipment lifespan beyond ten years under proper care conditions.

Market Trends Influencing Purchasing Decisions

Recent developments shaping buyer preferences include:

- Sustainability Focus: Emission-reducing technologies complying with stricter environmental regulations attract subsidies tax incentives certain regions incentivizing greener purchases despite higher initial outlays.

- Rental vs Ownership Shift: Some contractors opt short-term rentals avoid depreciation risks storage hassles especially smaller firms lacking capital reserves large upfront investments.

- After-Sales Support Expectations: Buyers increasingly prioritize suppliers offering comprehensive warranties training programs spare parts availability ensuring uninterrupted operations remote locations where delays costly.

Understanding these trends helps prospective buyers make informed decisions aligning budgetary constraints project requirements future scalability needs effectively balancing performance affordability trade-offs appropriately before committing funds purchase lease agreements alike .

Conclusion

Investing in a 100 TPH mobile jaw crusher capable of handling basalt involves careful evaluation beyond sticker price alone considering production demands maintenance obligations technological advancements marketplace dynamics collectively determining return-on-investment potential Ultimately selecting right model depends individual operational goals financial capacity ensuring maximum value derived throughout ownership period regardless application type geographical location involved .