Here is the 800-word article:

A Comprehensive Guide to Selecting the Right Stone Crusher

Choosing the correct stone crusher is a critical decision that directly impacts the productivity, cost-efficiency, and final product quality of any construction or mining operation. With various types of machinery available, making an informed choice requires a clear understanding of several key factors. This guide consolidates expert knowledge to help you navigate the selection process effectively.

Understanding the Core Types of Crushers

The first step in selection is understanding the fundamental mechanisms of different crushers. Each type is engineered for specific stages of the crushing process and material characteristics.

Jaw Crushers are primary crushers, known for their robust design and ability to handle large, raw feed material. They function like a giant V, with one stationary jaw and one moving jaw that compresses the rock against it. This compression force effectively breaks down large boulders into smaller, manageable sizes. They are ideal for hard, abrasive materials and are often the first machine in a crushing circuit.

Cone Crushers are typically used in secondary or tertiary crushing stages. They crush material between a rotating mantle and a stationary concave liner. Cone crushers are excellent for producing fine, well-graded aggregates and are highly efficient with medium to hard stones. Their ability to provide a consistent product size makes them a staple in aggregate production.

Impact Crushers, including Horizontal Shaft Impactors (HSIs) and Vertical Shaft Impactors (VSIs), utilize high-speed impact forces to break rock. HSIs are versatile for both primary and secondary roles, excellent for softer, less abrasive materials like limestone, and are known for producing a cubical product. VSIs specialize in shaping and fine crushing, creating high-quality sand and finely graded material.

Key Factors That Determine Your Choice

Selecting a crusher goes beyond just its type; it involves a detailed analysis of your project’s specific requirements.

Material Characteristics: The properties of the rock you are processing are paramount. You must consider its hardness, abrasiveness, density, and moisture content. For instance, a jaw crusher or cone crusher is better suited for hard, abrasive granite, while an impact crusher is more efficient for recycling concrete or crushing softer limestone.

Required Final Product: Define your desired output specifications clearly. What is the required final product size and shape? Do you need uniformly sized coarse aggregate or finely crushed sand? If producing cubical products for high-strength concrete is crucial, an impact crusher might be necessary. For consistent grading in road base layers, a cone crusher is often preferred.

Production Capacity: Your required tons-per-hour output is a major driver in machine selection. A smaller mobile plant might suffice for a short-term project with lower output demands. In contrast, a large-scale stationary quarry requiring thousands of tons per day will need a high-capacity primary jaw crusher followed by robust secondary cone crushers.

Mobility and Site Considerations

The physical constraints and nature of your project site play a significant role in determining whether you need a mobile or stationary setup.

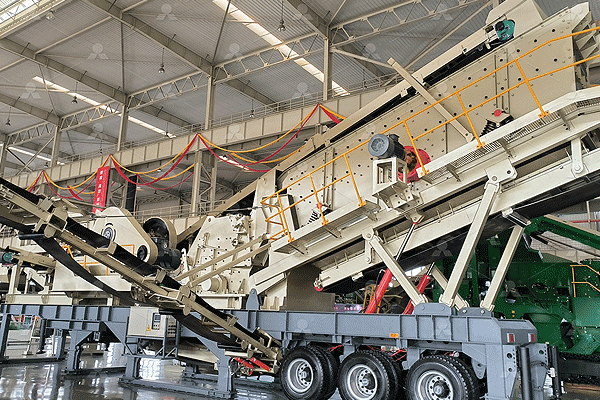

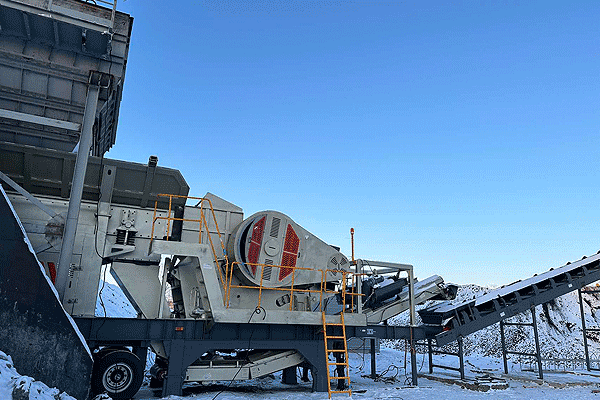

Mobile Crushers offer unparalleled flexibility. These track-mounted or wheeled units can be moved between sites or around a large quarry with relative ease. They are perfect for projects with multiple job sites, limited space, or shorter durations. The ability to process material on-site eliminates the need for trucking raw feed to a fixed location, saving time and transportation costs.

Stationary Plants are designed for long-term operations at a single location. They are typically larger, more robust systems with higher production capacities. A stationary plant often consists of multiple crushers (primary, secondary, tertiary) arranged in a circuit with screens and conveyors to achieve complex product specifications. While requiring a significant initial setup and infrastructure investment, they offer superior efficiency and volume output for permanent quarries.

Balancing Performance with Operational Costs

The initial purchase price is only one part of the financial equation; long-term operational costs are equally critical.

It’s important to understand that many factors influence equipment cost; different requirements lead to different configurations which naturally result in varying price points beyond just initial purchase price.. A crucial aspect is evaluating the Total Cost of Ownership (TCO). This includes energy consumption—some crushers are more energy-efficient than others—and maintenance expenses.

Wear parts are inevitable consumables in crushing operations.The rate at which parts like jaw plates,mantles,and blow bars wear down depends on material abrasiveness.Crushers designed with easy access for part replacement can significantly reduce downtime.Likewise,the availability of local service support ensures minimal disruption when maintenance is required.Investing in reliable equipment from famous brands often pays off through higher uptime,dependable performance,and accessible technical support over the machine’s entire lifespan,making it ultimately more cost-effective than opting based on price alone