How to Choose Secondary Crushing Equipment

Selecting the right secondary crushing equipment is a critical decision in any aggregate or mining operation. This stage follows primary crushing and is responsible for further reducing the size of the material to prepare it for final processing or direct use. The correct choice directly impacts overall plant efficiency, product quality, and operational costs. This guide consolidates expert knowledge to help you navigate the key factors in selecting the most suitable secondary crusher for your specific needs.

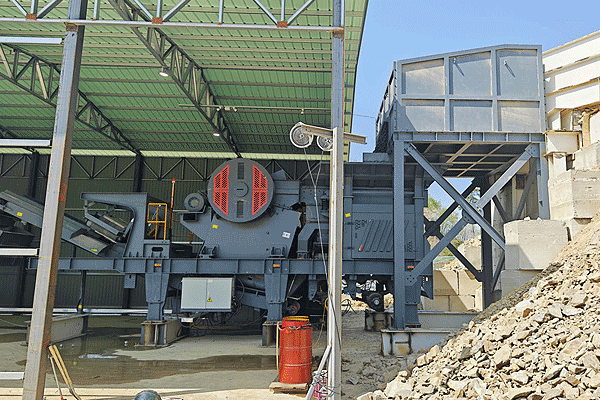

Understanding the Role of Secondary Crushers

Secondary crushers are not merely a smaller version of primary machines; they serve a distinct and vital purpose in the size reduction circuit. Their primary function is to take the coarse output from the primary crusher—which can range from several inches to over a foot in size—and reduce it further to a more manageable and specific product, typically between 1 inch and 3 inches.

This stage is crucial for shaping the final product and liberating valuable minerals locked within the rock. A well-chosen secondary crusher ensures consistent feed for downstream processes like tertiary crushing or screening, optimizing the entire production line. The fundamental goal is to achieve the desired product specification—be it for concrete aggregate, road base, or ballast—with maximum efficiency and minimal waste. Different types of crushers excel at producing different particle shapes and sizes, making the selection process pivotal to meeting your final product goals.

Key Factors Influencing Equipment Selection

Several interconnected factors must be carefully evaluated before settling on a specific type of secondary crushing equipment. Ignoring any of these can lead to suboptimal performance, frequent downtime, or unexpected costs.

First, analyze the material characteristics. The hardness, abrasiveness, density, and moisture content of the feed material are paramount. For instance, extremely hard and abrasive rocks demand robust machinery with high wear resistance, while sticky or high-moisture materials may require specialized designs to prevent clogging. The presence of silica is another critical consideration as it affects liner wear rates.

Second, consider your production capacity requirements. The crusher must be capable of handling your plant’s expected throughput without becoming a bottleneck. This involves matching the crusher’s capacity with that of your primary crusher and downstream equipment.

Third, define your final product specifications. What are the target size and shape of the end product? Some applications require precisely shaped cubical aggregates, while others are more forgiving. The desired product gradation will significantly narrow down your equipment options.

Finally, operational considerations such as plant mobility (stationary vs. portable setup), ease of maintenance, and available installation space are practical aspects that cannot be overlooked.

A Comparative Look at Common Crusher Types

The market offers several types of secondary crushers, each with unique operating principles and ideal applications.

Cone Crushers are among the most popular choices for secondary crushing. They work by compressing material between a gyrating mantle and a stationary concave liner. They are highly efficient for processing hard and abrasive materials and are renowned for their ability to produce a consistent, well-graded product with a good shape. Their closed-side setting allows for precise control over the final product size.

Impact Crushers, including horizontal shaft impactors (HSI), utilize high-speed impact forces to fracture rock. They are exceptionally effective at producing a highly cubical product, which is often desirable in concrete and asphalt applications. Impact crushers can also handle softer, less abrasive materials very efficiently. However, wear parts may experience a shorter lifespan when processing highly abrasive feed.

Jaw Crushers, though often used in primary roles, can sometimes serve as secondary crushers depending on the application and feed size. They function by compressing rock between a fixed and a moving jaw plate. Their simplicity and ruggedness make them a reliable choice.

Each type has its strengths; cone crushers excel in hardness and abrasion resistance, impact crushers lead in particle shape, while jaw crushers offer straightforward operation.

Operational Costs: Beyond Initial Investment

When evaluating secondary crushing equipment, it is essential to consider the total cost of ownership rather than just focusing on initial investment costs alone because there are many factors influencing price such as different requirements leading to varying configurations which result in different pricing structures altogether .

The two most significant ongoing costs are typically wear part consumption and energy consumption. Highly abrasive feed material will rapidly wear out liners, mantles, blow bars, and other internal components leading not only towards replacement part expenses but also labor costs associated with change-outs plus related downtime periods impacting overall productivity levels negatively if not planned properly beforehand . Generally speaking , cone crushers tend towards having higher wear part costs per ton processed compared against impact crushers when dealing with non-abrasive feeds however this dynamic can reverse completely when material abrasiveness increases significantly .

Energy efficiency represents another major long-term expense area where modern designs often incorporate features aimed at reducing power draw per ton of material processed thereby lowering operational expenditures over time substantially . Regular maintenance schedules along with easy access points designed into machinery help minimize labor hours required keeping equipment running smoothly thus further controlling lifetime ownership expenses effectively .

Optimizing Performance Through Proper Maintenance

To ensure your secondary crushing equipment delivers peak performance over its entire lifespan implementing proactive maintenance strategy becomes absolutely necessary since neglecting this aspect leads inevitably toward unexpected breakdowns causing costly production halts alongside potential damage extending beyond immediate repairs needed urgently .

Establishing routine inspection schedules forms foundation any successful maintenance program focusing particularly on monitoring wear parts like liners concaves mantles blow bars etc replacing them before they become too thin risking catastrophic failure damaging other expensive components within system unnecessarily . Regularly checking lubrication systems ensuring oil remains clean at correct levels proves vital especially for cone crushers where contaminated lubricant could result severe bearing damage quickly .

Furthermore keeping track operational parameters such as drive belt tensions hydraulic pressures amp draws helps identify potential problems early stages allowing corrective actions taken before escalating into major issues requiring extensive downtime periods resolve adequately training operational staff recognize signs abnormal operation noise vibration contributes significantly towards maintaining high equipment availability reliability ultimately protecting your investment maximizing return achieved from it fully .