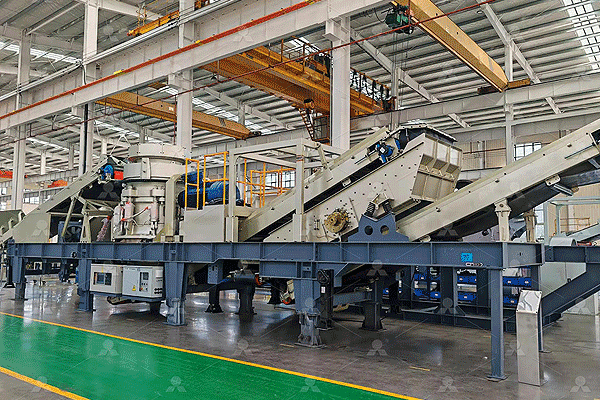

Efficient Fine Crushing of Iron Ore with HPT Cone Crusher

Introduction

The HPT cone crusher is a high-performance crushing machine designed for demanding applications such as iron ore processing. With an output capacity of 220 tons per hour (tph), it excels in fine crushing operations, delivering consistent particle size reduction and improved downstream processing efficiency. Its advanced hydraulic system and optimized cavity design ensure reliable performance in abrasive environments, making it a preferred choice for mineral processing plants.

Key Features Enhancing Performance

The HPT cone crusher incorporates several innovative features that contribute to its superior efficiency in iron ore fine crushing. Its multi-cylinder hydraulic system provides overload protection and precise adjustment capabilities, ensuring stable operation under varying feed conditions. The laminated crushing principle minimizes wear on critical components, extending service life and reducing maintenance costs. Additionally, the automated control system optimizes production while maintaining desired product fineness.

Optimized Crushing Chamber Design

A well-designed crushing chamber is crucial for achieving high-quality fines in iron ore processing. The HPT cone crusher utilizes an optimized cavity profile that enhances inter-particle crushing, resulting in a more uniform product size distribution. This design reduces recirculation load and improves overall energy efficiency. By adjusting the eccentric bushing speed and stroke, operators can fine-tune the crusher’s performance to meet specific requirements without compromising throughput or product quality.

Energy Efficiency and Cost Savings

Energy consumption is a major concern in mineral processing operations. The HPT cone crusher addresses this challenge through intelligent power management and minimized friction losses within its moving parts. Compared to traditional crushers, it delivers higher productivity per unit of energy consumed, translating into significant cost savings over time. Furthermore, its durable construction reduces downtime associated with component replacement, enhancing overall operational economics.

Maintenance and Reliability

Reliability is paramount in continuous mining operations where unplanned shutdowns can be costly. The HPT cone crusher features simplified maintenance procedures facilitated by accessible inspection points and replaceable wear parts designed for quick installation. Advanced sealing systems prevent dust ingress into critical components while ensuring smooth lubrication flow—key factors contributing to prolonged equipment lifespan even under harsh operating conditions typical of iron ore processing plants worldwide today!

By combining robust engineering with intelligent automation features tailored specifically toward demanding applications like fine-crushing tasks involving abrasive materials such as those found throughout various stages involved during extraction processes globally—this machine stands out among competitors offering similar solutions elsewhere across industry sectors requiring heavy-duty machinery capable handling toughest challenges thrown their way daily basis without fail whatsoever!