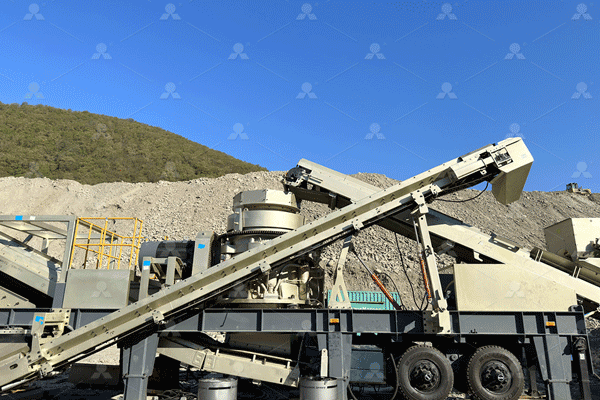

HST Cone Crusher: A Cost-Effective Solution for Manganese Ore Processing at 220 TPH

Introduction to HST Cone Crusher

The HST cone crusher is a high-efficiency crushing machine designed for processing hard and abrasive materials like manganese ore. With a capacity of 220 tons per hour (TPH), it offers reliable performance in mineral processing plants. Its advanced hydraulic system ensures smooth operation, while its robust construction minimizes maintenance downtime. This makes it an ideal choice for mining operations looking to optimize productivity while keeping costs under control.

Key Features of the HST Cone Crusher

The HST cone crusher stands out due to several innovative features:

- Hydraulic Adjustment System: Allows quick and precise setting changes, improving efficiency.

- High Crushing Ratio: Delivers fine and uniform output, reducing the need for secondary crushing.

- Energy Efficiency: Optimized design lowers power consumption compared to traditional crushers.

- Durable Components: High-quality manganese steel liners extend service life even under heavy-duty conditions.

These features make the HST cone crusher a preferred choice for processing manganese ore at competitive factory prices.

Advantages in Manganese Ore Processing

Manganese ore is notoriously tough and abrasive, demanding robust equipment. The HST cone crusher excels in this application by:

- Reducing Wear & Tear: Its specialized liners resist abrasion, lowering replacement costs.

- Consistent Output Size: Ensures uniform particle size for downstream processes like smelting or beneficiation.

- Minimal Downtime: Easy maintenance access and automated controls reduce operational interruptions.

For mines targeting 220 TPH throughput, this crusher offers a balance of performance and cost-effectiveness.

Factory Price Considerations

When evaluating factory pricing for an HST cone crusher, buyers should consider:

- Long-Term Savings: Higher upfront costs may be offset by lower energy use and reduced maintenance expenses.

- Customization Options: Some manufacturers offer tailored configurations to match specific ore characteristics.

- After-Sales Support: Reliable suppliers provide spare parts availability and technical assistance, ensuring uninterrupted operation.

Investing in a well-built cone crusher at a reasonable factory price can significantly enhance profitability in manganese ore processing operations.

Conclusion

The HST cone crusher is a high-performance solution for processing manganese ore at 220 TPH efficiently and economically. Its advanced design, durability, and cost-saving benefits make it a smart investment for mining operations seeking long-term reliability without compromising on quality or productivity. By choosing the right model at a competitive factory price, businesses can maximize their return on investment while maintaining consistent production output.