Title: Impact Crushers in Indonesia: Powering Construction and Mining Growth

Industry Background

Indonesia’s economy is growing fast. Infrastructure and mining are key drivers. The government is investing heavily in roads, ports, and new cities. This creates huge demand for raw materials like limestone, andesite, and coal. Impact crushers are essential for processing these materials. They turn large rocks into specific sizes for construction and industrial use. The market is competitive. Efficiency and reliability are crucial for success.

Product and Technology

Impact crushers use impact force to break materials. They are not like jaw crushers that use pressure. A high-speed rotor hits the incoming feed. This action shatters the rocks against hardened aprons.

Key Features of Modern Impact Crushers:

- High Reduction Ratio: They can significantly reduce rock size in a single pass.

- Excellent Cubical Shape: Produces uniform, cube-shaped aggregate, ideal for high-quality concrete.

- Adjustable Output Size: The gap between the rotor and aprons can be adjusted to control final product size.

- Robust Construction: Built with heavy-duty materials to handle abrasive Indonesian rocks.

| Feature | Benefit |

|---|---|

| Hydraulic Adjustment | Allows easy setting changes without stopping the machine. |

| Wear-resistant Liners | Increases service life and reduces downtime for part replacement. |

| High-Speed Rotor | Delivers powerful impact for efficient crushing of medium-hard rocks. |

Market Trends & Applications

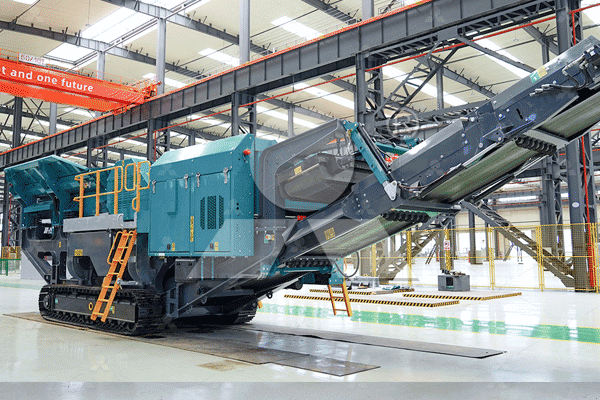

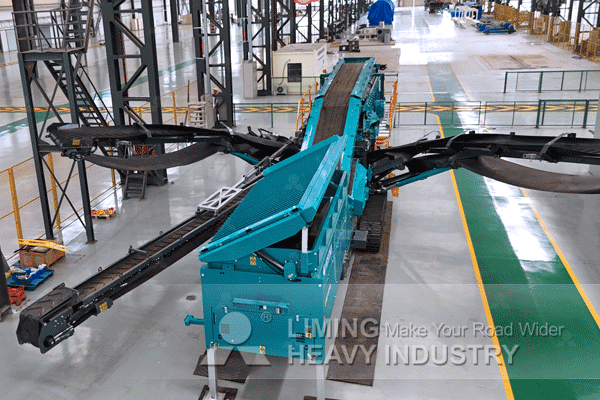

Demand is shifting towards mobile impact crushers. They offer great flexibility for multiple site projects. Quarry operators value their quick setup and mobility.

Primary Applications in Indonesia:

- Mining: Crushing coal and metallic ores.

- Construction: Producing aggregates for concrete and asphalt from limestone and granite.

- Recycling: Processing demolition waste like concrete and asphalt for reuse.

The trend is towards more sustainable operations. Energy-efficient motors are now a standard request.

Future Outlook

The future is smart and connected. Crushers will feature more IoT sensors for real-time monitoring. Predictive maintenance will prevent unexpected breakdowns.

Automation will increase for safer operation.

Sustainability will drive innovation in dust control and noise reduction.

Hybrid power systems (diesel-electric) may become more popular to cut fuel costs.

Frequently Asked Questions (FAQ)

-

What is the main advantage of an impact crusher?

It produces a well-shaped, cubical product, which is superior for concrete mix. -

What materials can it crush in Indonesia?

It is ideal for medium-hard rocks like limestone, sandstone, and basalt common in Indonesian quarries. -

How about wear parts replacement?

Wear parts like blow bars need regular inspection. Using local service partners ensures quick replacement to minimize downtime. -

Can it be used for recycling?

Yes, specially designed models can effectively crush construction and demolition waste.

-

What about after-sales support?

Choose a supplier with a strong local presence in Indonesia for reliable spare parts and technical service.

Case Study: Boosting Production in a Java Quarry

A quarry in Central Java was using an old jaw crusher. Their product shape was poor. It did not meet specifications for a major infrastructure project.

They invested in a modern mobile impact crusher.

The new machine was installed quickly.

It immediately improved the product shape.

Production capacity increased by over 30%.

The consistent, high-quality aggregate helped them secure more contracts.

Ready to Improve Your Crushing Operation?

Find the right impact crusher for your specific needs in Indonesia.

Our experts are here to help you choose the best model.

[Contact Us Today for a Free Quote & Consultation]