Title: Robust Crushing Solutions for Hard Rock: The Indonesia 280-320 TPH Andesite Plant

Industry Background

The global crushing machinery sector is expanding. Demand is driven by global infrastructure development. Hard rock mining is a key market. Countries like Indonesia are investing heavily in construction. This requires reliable, high-capacity crushing plants. Efficient processing of materials like andesite is crucial for project success.

Product and Technology

This plant uses a full set of robust equipment. It is designed for high-volume production and durability.

- Primary Crushing: Jaw Crusher. This machine handles the initial breakdown of large andesite boulders. It provides high compressive strength and stability.

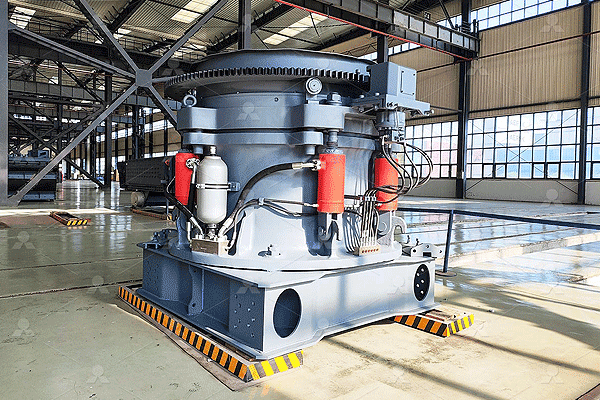

- Secondary Crushing: Cone Crusher. Essential for producing a well-shaped, finer product. Its interparticle crushing action is ideal for hard and abrasive rocks.

- Tertiary Crushing: Another Cone Crusher or Impact Crusher. This stage further refines the final product to meet specific size specifications.

- Auxiliary Equipment: This includes Vibrating Feeders, Screens, and Conveyor Belts. They ensure smooth material flow and efficient sorting.

| Equipment Type | Key Function | Ideal For |

|---|---|---|

| Jaw Crusher | Primary Size Reduction | Large, raw feed material |

| Cone Crusher | Secondary/Tertiary Crushing | Shaping & producing cubical products |

| Vibrating Screen | Material Classification | Sorting crushed rock into sizes |

Market Trends & Application

There is a clear trend towards stationary crushing plants for large-scale projects. High capacity (250-400 TPH) is a common requirement. Automation is becoming standard for optimization.

Andesite crushed in this plant is primarily used for:

- Concrete Aggregate: Provides strong foundations for buildings.

- Road Base Material: Forms a stable layer for highway construction.

- Railway Ballast: Supports railway tracks.

Future Outlook

The industry is moving towards smarter solutions.

- Digitalization: IoT sensors will monitor machine health in real-time.

- Energy Efficiency: New crusher designs focus on reducing power consumption.

- Sustainability: Dust suppression and noise control systems are now essential.

Frequently Asked Questions (FAQ)

-

What is the typical lead time for such a plant?

- Lead time varies but generally ranges from 8 to 12 weeks for a standard configuration.

-

What after-sales services are provided?

- We offer comprehensive support including installation supervision, operator training, and readily available spare parts.

-

Can the plant be customized for different materials?

- Yes. Crusher settings, screen meshes, and other components can be tailored to process various hard rocks like basalt or granite.

Case Study: Indonesia 280-320 TPH Andesite Crushing Plant

A major Indonesian contractor needed a reliable solution for a national highway project.

- Challenge: Process extremely hard and abrasive andesite at a steady rate of over 300 tons per hour.

- Solution: We supplied a complete crushing circuit featuring a robust Jaw Crusher and two high-efficiency Cone Crushers.

- Outcome: The plant consistently achieved the target output of 280-320 TPH. The final product quality exceeded specifications for road base material, ensuring project timelines were met efficiently.

Ready to Optimize Your Crushing Operation?

Our experts are here to help you select the right machinery for your specific needs and material.

[Contact Us Today for a Custom Quote]