Title: Portable Power for Tough Rock: The Indonesia 400t/h Andesite Crushing Plant

Industry Background

The global construction sector is growing. Demand for high-quality aggregates is strong. Infrastructure projects drive this need. Portable crushing plants are key. They offer mobility and efficiency. They reduce transport costs. They are ideal for remote sites. The market favors flexible, high-capacity solutions.

Product and Technology

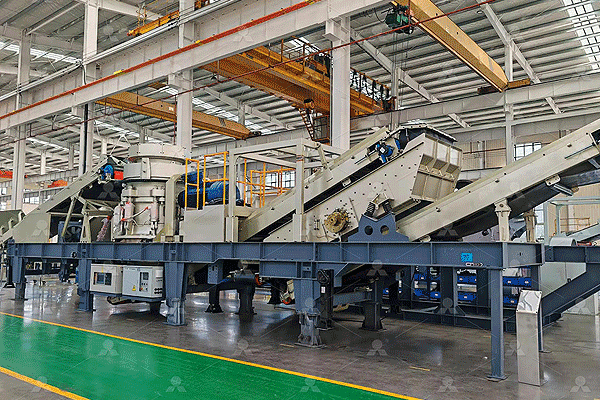

This plant crushes tough andesite. It delivers 400 tons per hour. Key components ensure top performance.

- Primary Jaw Crusher: Handles large raw rocks. It is robust and reliable.

- Secondary Cone Crusher: Provides precise crushing. It produces well-shaped aggregates.

- Tertiary Impact Crusher: Creates fine, cubicle products. It is ideal for sand making.

- Vibrating Screens: Sort materials into different sizes efficiently.

- Portable Chassis: Allows quick setup and movement between sites.

Key Equipment Specifications

| Component | Model Example | Key Feature |

|---|---|---|

| Primary Crusher | JC Series Jaw | High crushing ratio, sturdy build |

| Secondary Crusher | HP Series Cone | Automated control, excellent particle shape |

| Tertiary Crusher | VSI Impact Crusher | High cube output, sand production |

| Vibrating Screen | 3YK3072 | Multi-layer screening, high efficiency |

Market Trends & Applications

Portable plants are increasingly popular. They support major infrastructure work. Key applications include:

- Road Construction: Providing base and sub-base materials.

- Building Foundations: Supplying aggregates for concrete.

- Railway Ballast: Producing the specific stone size needed.

The trend is toward integrated, intelligent systems. Automation reduces human error. Remote monitoring boosts uptime.

Future Outlook

The future is smart and green. Digitalization will be central. IoT sensors will predict maintenance needs. Automation will optimize production lines. Sustainability is a major driver. Plants will use more electric power. Dust and noise control will improve. Hybrid energy systems may become standard.

Frequently Asked Questions (FAQ)

-

Q: What is the typical setup time for this plant?

A: Setup is very fast. It often takes less than one day. No foundation work is needed. -

Q: Can it handle other types of rock?

A: Yes. The configuration is optimized for andesite. But it can also process basalt and granite effectively. -

Q: What about after-sales service and parts?

A: Global service networks provide support. Critical spare parts are available worldwide to minimize downtime. -

Q: Is the final product size adjustable?

A: Absolutely. Screen decks and crusher settings can be changed. This allows for different aggregate specifications.

Case Study: Project “Java Highway”

- Challenge: A highway project in remote Indonesia needed a steady aggregate supply. Transporting material from a fixed quarry was too costly and slow.

- Solution: The 400t/h portable andesite crushing plant was deployed near the site.

- Outcome: The project achieved a reliable material supply on-site.

- Production reached 380-410 tons per hour consistently.

- Transport costs were slashed by over 60%.

- Project timeline was shortened by months.

Ready to Boost Your Project’s Efficiency?

This portable plant delivers power, mobility, and results.

Contact us today for a detailed quote tailored to your specific needs