Title: Robust Crushing Solutions for Indonesian Andesite

Industry Background

The construction sector in Indonesia is growing rapidly. Major infrastructure projects are driving this growth. Government initiatives are a key factor. Demand for high-quality building materials is strong. Andesite aggregate is essential for these projects. It provides durability and strength. The market for crushing plants is very competitive. Efficiency and reliability are crucial.

Products and Technology

Modern crushing plants use advanced technology. They are designed for hard materials like andesite.

- Jaw Crushers: These are used for primary crushing. They handle large raw andesite rocks. High pressure resistance is a key feature.

- Cone Crushers: Ideal for secondary crushing. They produce a more uniform particle size. Hydraulic systems allow easy adjustment.

- Impact Crushers: Best for producing fine aggregates. They offer good cubical shape output.

Key Equipment Comparison

| Crusher Type | Best For | Output Size | Key Feature |

|---|---|---|---|

| Jaw Crusher | Primary Crushing | Large to Medium | High Durability |

| Cone Crusher | Secondary Crushing | Medium to Fine | Precise Control |

| Impact Crusher | Tertiary/Fine Crushing | Fine to Cubic | Shape Optimization |

Market Trends & Applications

There is a high demand for high-specification aggregates. Road base layers require specific andesite grades. Concrete production needs consistent, clean aggregate.

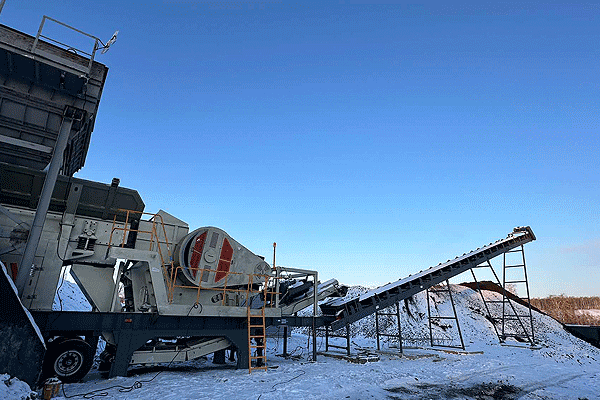

- Trend: Move towards mobile crushing plants. They offer flexibility for multiple site locations.

- Trend: Automation for better efficiency and lower labor costs.

- Application: Heavy-duty road construction.

- Application: High-strength ready-mix concrete.

- Application: Railway ballast.

Future Outlook

The industry will see more digital integration. IoT sensors will monitor machine health in real-time. Sustainability will be a major focus.

- Electric Drives: Plants will shift to electric power for lower emissions.

- Dust Control: Advanced suppression systems will become standard.

- Smart Plants: Fully automated, data-driven operations are the future.

Frequently Asked Questions (FAQ)

-

Q: What is the best crusher for hard andesite?

- A: A combination of a robust jaw crusher and a cone crusher is most effective.

-

Q: What is the typical lead time for a complete plant?

- A: Lead times vary from 8 to 16 weeks, depending on plant configuration and customization.

-

Q: Do you provide on-site installation support?

- A: Yes, we offer comprehensive technical support and supervised installation.

-

Q: Can the plant be made portable?

- A: Absolutely. Track-mounted mobile plants are available for project mobility.

Case Study: Sumatra Highway Project

- Challenge: Produce 2 million tons of high-quality andesite aggregate across three remote sites.

- Solution: Deployment of three modular crushing plants, each with a primary jaw crusher and secondary cone crusher.

- Outcome: Consistent aggregate quality met strict government specs. The modular design allowed quick relocation, reducing downtime by 30%.

Request a Custom Quote Today

Need a reliable crushing solution for your andesite project? Our experts are ready to help you design the perfect plant.

Contact us now for a free consultation and detailed quotation.