Jaw Crusher 100 TPH Price in Kazakhstan: A Comprehensive Guide

Introduction

Jaw crushers are essential equipment in mining, construction, and aggregate industries due to their ability to crush hard materials efficiently. In Kazakhstan, where mining and infrastructure projects are expanding rapidly, the demand for reliable crushing machinery is high. A 100 TPH (tons per hour) jaw crusher is a popular choice for medium-scale operations. This article explores key factors influencing its price, performance considerations, and purchasing tips without referencing specific brands or companies.

Factors Affecting Jaw Crusher Pricing

The cost of a 100 TPH jaw crusher in Kazakhstan depends on several variables:

1. Material & Build Quality – High-grade steel and wear-resistant components increase durability but also raise costs.

2. Production Capacity – Machines with higher throughput (like 100 TPH) are priced higher than lower-capacity models.

3. Energy Efficiency – Advanced models with optimized power consumption may have a premium price but reduce long-term operational costs.

4. Local vs. Imported Units – Import taxes, shipping fees, and currency exchange rates impact final pricing for foreign-made crushers.

5. After-Sales Support – Suppliers offering warranties, spare parts availability, and maintenance services often charge more upfront but provide better value over time.

Buyers should balance initial investment against long-term operational efficiency when evaluating prices.

Key Features of a Reliable 100 TPH Jaw Crusher

When selecting a jaw crusher for Kazakhstan’s rugged conditions, consider these features:

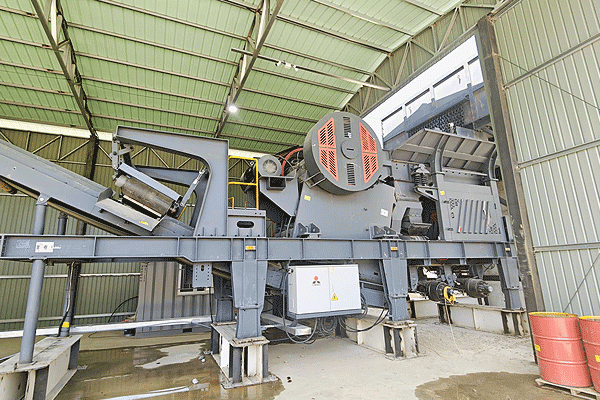

- Robust Construction: Reinforced frames and high-manganese steel jaws withstand abrasive materials like granite or basalt.

- Adjustable Settings: Hydraulic or mechanical toggle adjustments allow precise control over output size (e.g., 50–150 mm).

- Easy Maintenance: Accessible lubrication points and replaceable wear parts minimize downtime.

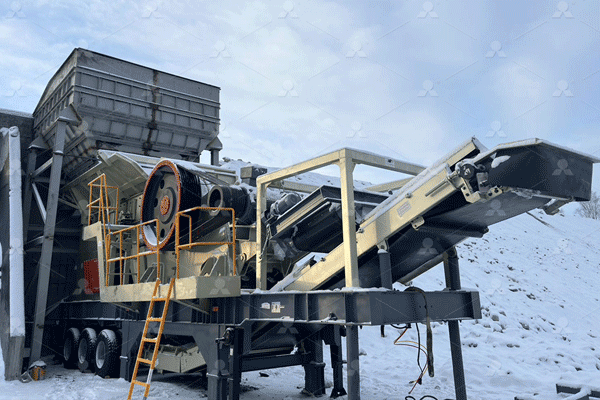

- Mobility Options: Some models offer track-mounted or wheeled configurations for flexible deployment across job sites.

- Dust Suppression Systems: Essential for compliance with environmental regulations in mining zones.

- Entry-level 100 TPH jaw crushers start around $50,000–$70,000, suitable for small contractors needing basic functionality.

- Mid-range models ($80,000–$120,000) offer better efficiency and longevity with advanced features like automated controls or hybrid power options (diesel/electric).

- Premium units exceeding $150,000 include smart monitoring systems (IoT-enabled sensors) and superior after-sales packages tailored to industrial-scale projects like quarrying or ore processing plants near major cities such as Almaty or Nur-Sultan (Astana). Seasonal promotions from suppliers may also influence pricing—buyers should monitor industry trade fairs held locally before committing to purchases outrightly!

A well-designed crusher improves productivity while reducing repair costs—critical factors in Kazakhstan’s harsh climate and remote locations.

Market Trends & Price Range Expectations

In Kazakhstan’s competitive market:

Where To Buy & Negotiation Tips

Purchasing channels vary widely across regions within this Central Asian nation so here’s how buyers can secure favorable deals:

1️⃣ Local Distributors – Established vendors provide quicker delivery times plus regional technical support albeit at slightly marked-up rates compared directly importing yourself via international manufacturers’ websites instead which requires handling logistics independently though potentially saving money overall if volumes justify expenses incurred during customs clearance processes etcetera…

2️⃣ Online Marketplaces – Platforms specializing heavy machinery sales sometimes list refurbished/second-hand options costing significantly less than brand-new equivalents however thorough inspections must be conducted prior transactions since counterfeit products occasionally surface too unfortunately especially when dealing unknown sellers anonymously online without verifiable credentials attached securely behind profiles created recently just days ago perhaps even hours earlier suspiciously enough warrant caution always!

3️⃣ Direct Imports – Large enterprises might prefer sourcing overseas factories cutting middlemen margins entirely yet logistical complexities including import duties (~15% average), transportation delays due border checks alongside language barriers could complicate matters unnecessarily unless experienced handlers manage shipments professionally ensuring smooth arrivals ultimately benefiting bottom lines substantially longer term perspectives considered carefully beforehand obviously…

Negotiate strategically by requesting bulk discounts financing plans extended warranties free training sessions operators maintenance crews included within package deals wherever possible maximizing returns investments made wisely upfront rather regretting missed opportunities later down road inevitably otherwise…

Conclusion

Investing wisely requires understanding both technical specifications financial implications involved acquiring dependable equipment capable meeting demands placed upon them consistently under challenging working environments found throughout vast landscapes spanning entire country borders stretching far wide expanses steppes deserts mountainous terrains alike requiring ruggedness reliability above else ensuring uninterrupted workflows maximizing profitability sustainably future generations come ahead prosperously together harmoniously united common goals shared collectively amongst stakeholders industry-wide universally accepted norms standards upheld rigorously always!