Understanding the Pricing of a 150 TPH Jaw Crusher in Saudi Arabia

Introduction

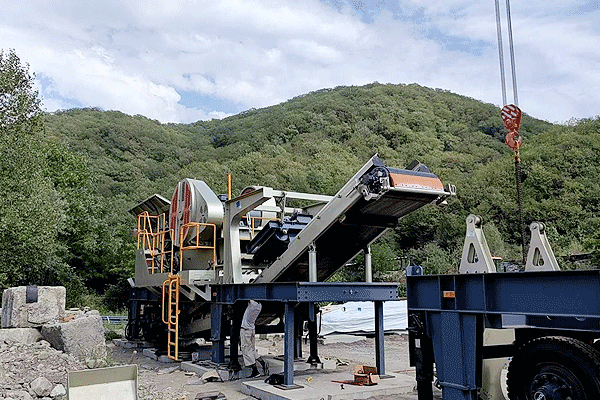

A jaw crusher is a primary crushing machine widely used in mining, construction, and aggregate industries. In Saudi Arabia, where infrastructure and industrial projects are rapidly expanding, the demand for reliable crushing equipment remains high. A 150-ton-per-hour (TPH) jaw crusher is a mid-range model suitable for medium-scale operations. This article explores factors influencing its price, market trends, and considerations for buyers in Saudi Arabia.

Each section below provides standalone insights while contributing to a comprehensive understanding of jaw crusher pricing in the region.

—

Key Factors Affecting Jaw Crusher Pricing

1. Production Capacity and Efficiency

A 150 TPH jaw crusher balances output and operational costs. Higher-capacity models generally cost more due to reinforced structures and advanced crushing mechanisms. Buyers should assess whether this capacity aligns with their project requirements to avoid overspending or underperformance.

2. Material and Build Quality

Durable materials like high-grade steel increase longevity but also raise manufacturing costs. In Saudi Arabia’s harsh climate—extreme heat and abrasive sand—investing in corrosion-resistant components ensures long-term reliability despite higher initial expenses.

3. Technology and Automation Features

Modern jaw crushers may include automated adjustments, real-time monitoring systems, or energy-efficient motors. While these features improve productivity, they also contribute to higher prices compared to basic models without such enhancements.

4. Import Duties and Logistics

Since Saudi Arabia imports most heavy machinery, shipping costs, customs tariffs, and local taxes significantly impact final prices. Buyers should account for these additional expenses when budgeting for equipment procurement.

—

Market Trends Influencing Jaw Crusher Prices

1. Growing Demand in Construction Sector

Saudi Arabia’s Vision 2030 initiative drives infrastructure development, increasing demand for crushing equipment like the 150 TPH jaw crusher. High demand can lead to competitive pricing but may also cause supply shortages temporarily inflating costs during peak periods.

2.Fluctuations in Raw Material Costs

Steel prices directly affect manufacturing expenses globally; any volatility leads to adjustments in machinery pricing worldwide including Saudi markets where suppliers adjust quotes accordingly based on current material rates.

3.Local vs International Suppliers Competition

Local distributors sometimes offer better after-sales support than international sellers but might charge premiums due limited competition whereas global brands compete aggressively lowering margins yet adding logistical complexities buyers must consider before purchasing decisions are made.

—

Considerations When Buying A Jaw Crusher In Saudi Arabia

1.After-Sales Support Availability

Reliable maintenance services spare parts availability crucial desert conditions where downtime costly ensure supplier has strong service network within country avoid delays repairs replacements critical situations arise unexpectedly during operations phase project lifecycle .

2.Energy Consumption And Operational Costs

Electricity fuel consumption varies across different models opting energy-efficient unit reduces long-term running expenses especially important regions like Middle East where power generation relies heavily fossil fuels making efficiency key factor total cost ownership calculations .

3.Compliance With Local Regulations

Saudi Arabian authorities enforce strict safety environmental standards ensuring compliance avoids fines operational disruptions verify whether chosen model meets all regulatory requirements prior installation site avoid legal complications later stages usage period .

—

Conclusion: Making An Informed Purchase Decision

Purchasing a 150 TPH jaw crusher requires careful evaluation beyond just sticker price considering factors such as production needs durability technological advancements market dynamics logistical challenges By weighing these aspects buyers can select optimal machine delivers value money while meeting specific operational demands unique harsh environment found throughout kingdom Ultimately informed decision leads smoother project execution greater return investment over time .