Jaw Crusher for Limestone: A Comprehensive Guide to 100 TPH Capacity in Russia

Introduction

Crushing limestone efficiently requires robust and reliable equipment, and jaw crushers remain one of the most popular choices for primary crushing applications. In Russia, where limestone deposits are abundant, a jaw crusher with a capacity of 100 tons per hour (TPH) is often sought after for mining, construction, and aggregate production. This article explores the key aspects of selecting, operating, and maintaining a jaw crusher for limestone processing at this capacity while addressing pricing considerations specific to the Russian market.

—

Why Choose a Jaw Crusher for Limestone?

Limestone is a relatively soft sedimentary rock but can be abrasive due to its silica content. A jaw crusher excels in handling such materials due to its:

- High Reduction Ratio: Capable of reducing large limestone blocks into smaller fragments in a single pass.

- Simple Design: Fewer moving parts compared to other crushers, reducing maintenance complexity.

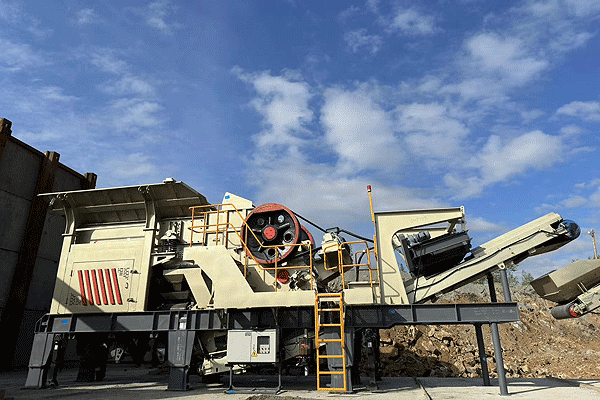

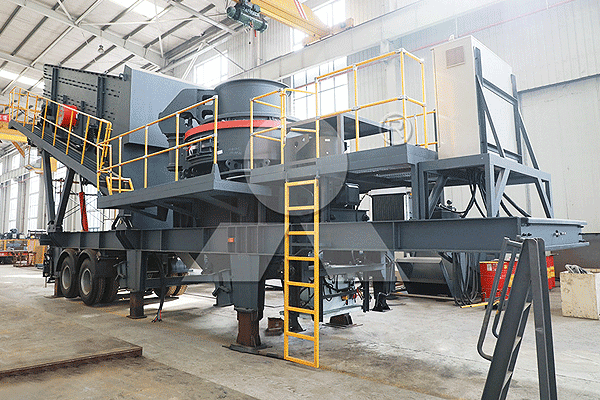

- Versatility: Suitable for both stationary and mobile crushing setups.

- New domestic models typically range between $50,000–$90,000 USD depending on specifications.

- Imported units from famous brands may cost upwards of $120,000 USD due to higher manufacturing standards.

For operations requiring 100 TPH output in Russia, selecting a well-designed jaw crusher ensures consistent performance while minimizing downtime.

—

Key Features of a 100 TPH Jaw Crusher

When evaluating jaw crushers for limestone processing at 100 TPH capacity, consider these essential features:

1. Feed Opening Size

A larger feed opening allows bigger limestone chunks to enter the crushing chamber without pre-breaking. For 100 TPH output, an opening between 600mm x 900mm is typically sufficient.

2. Motor Power

A robust motor ensures smooth operation under heavy loads. Depending on hardness variations in Russian limestone deposits, motors ranging from 75 kW to 110 kW are commonly used for this capacity range.

3. Wear-Resistant Components

Since limestone can be abrasive, manganese steel jaws and side liners enhance durability and prolong service life.

4. Adjustable Discharge Setting

Precise control over product size is crucial for meeting different application requirements (e.g., road base vs. concrete aggregate). Hydraulic adjustment mechanisms simplify this process.

—

Price Considerations in Russia

The cost of a jaw crusher capable of processing limestone at 100 TPH varies based on several factors:

1. Domestic vs Imported Equipment

Russian-made crushers may offer lower upfront costs due to reduced shipping expenses and tariffs compared to imported models from famous brands.

2. New vs Used Units

While new units guarantee reliability and warranty coverage, used or refurbished jaw crushers can provide significant savings—though thorough inspection is necessary before purchase.

3. Additional Costs

Beyond the base price, consider expenses such as installation, spare parts inventory (especially wear components), and potential modifications required for local conditions (e.g., extreme weather resilience).

As of recent market trends in Russia:

—

Operational Best Practices

Maximizing efficiency while minimizing wear requires adherence to best practices:

1. Proper Feeding Techniques

Avoid uneven loading or oversized material beyond design limits—use vibrating feeders if necessary.

2.Regular Lubrication & Inspection

Ensure bearings receive timely grease replenishment; inspect toggle plates periodically for cracks or excessive wear.

3.Optimizing Crushing Parameters

Adjust speed settings accordingto feed size variations—finer adjustments improve product consistency without overloading machinery unnecessarily .

—

Maintenance Tips To Extend Lifespan

Routine upkeep prevents costly breakdowns :

Scheduled Component Replacement

Replace worn-out jaws before they degrade further—this avoids secondary damage elsewhere within system .

Cleaning Debris Buildup

Limestone dust accumulation affects moving parts ; compressed air cleaning helps maintain smooth operation .

Monitoring Vibration Levels

Unusual vibrations indicate misalignment issues requiring immediate attention .

—

Conclusion

Selecting , operating ,and maintaininga jawcrusherforlimestoneprocessingat100TPHrequirescarefulconsiderationoftechnical specifications,pricingfactors,andlocalmarketconditionsinRussia.Withproperplanningandefficientmaintenancepractices,theinvestmentcanprovideyearsreliableperformancewhilemeetingproductiontargetsconsistently .