Jaw Crushers: The Ultimate Solution for Crushing Rock, Concrete, Asphalt, and Granite

Introduction

In the world of material reduction and aggregate production, few machines are as fundamental and versatile as the jaw crusher. This robust piece of equipment serves as a primary crusher across numerous industries, from mining and quarrying to construction and demolition recycling. Its primary function is to handle the initial size reduction of large, hard, and abrasive materials. Specifically engineered for durability and efficiency, modern jaw crushers are capable of processing some of the toughest substances on earth, including granite, reinforced concrete, asphalt, and various types of rock. This article explores the core principles, key features, operational benefits, and critical selection criteria for these indispensable machines.

The Core Working Principle of a Jaw Crusher

Understanding how a jaw crusher operates is key to appreciating its effectiveness. The machine’s functionality is based on a straightforward but powerful compressive crushing action. It consists of two vertical jaws: one is stationary, known as the fixed jaw, while the other moves in a rhythmic motion and is called the swing jaw. These jaws form a V-shaped chamber where the material to be crushed is fed.

As the swing jaw moves towards the fixed jaw, it exerts immense pressure on the material trapped between them. This action breaks the larger pieces into smaller fragments. The rhythmic movement continues until the crushed material is small enough to pass through the gap at the bottom of the chamber, known as the closed-side setting (CSS). This gap is adjustable, allowing operators to control the final product size. The process is cyclical and highly efficient, designed to maximize throughput while minimizing energy consumption per ton of material processed.

Key Features for Enhanced Performance and Durability

Modern jaw crushers incorporate several design features that significantly boost their performance and service life when dealing with abrasive materials. A critical component is the jaw plates or liners. These are typically made from high-grade manganese steel because of its exceptional work-hardening properties; it becomes harder as it is subjected to impact and pressure, thereby extending its wear life.

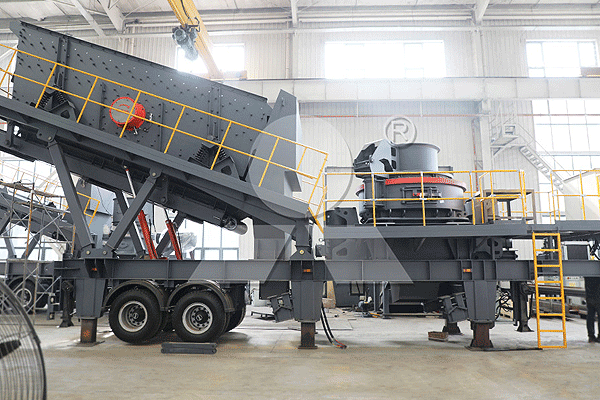

The frame construction is another vital aspect. Heavy-duty frames are often fabricated from high-strength steel plate or cast steel to withstand the tremendous forces generated during crushing. Furthermore, many contemporary models feature a hydraulic adjustment system for quickly and safely changing the CSS. This allows for precise control over product sizing without requiring extensive downtime or manual labor. Advanced models may also include an automatic toggle lubrication system that ensures critical bearings are consistently protected from contamination and friction.

Applications Across Different Materials

The true strength of a jaw crusher lies in its adaptability to various feed materials.

- Granite and Hard Rock: As one of the hardest natural stones, granite demands a crusher with immense power and robust construction. Jaw crushers are perfectly suited for primary crushing in granite quarries.

- Concrete and Reinforced Concrete: In construction and demolition recycling, jaw crushers excel at breaking down concrete slabs and structures.

- Asphalt: Milled asphalt or large chunks from road plans can be efficiently processed through a jaw crusher for reuse as a base material in new pavement.

- General Rock: For quarrying operations involving limestone, basalt, or other types of rock.

Factors Influencing Machine Selection

Choosing an appropriate machine requires careful consideration of several factors beyond just raw power.

- Feed Material Characteristics: The hardness.

- Required Production Capacity: The desired output in tons per hour will directly influence.

- Final Product Specifications: The target size and gradation of the crushed material determine.

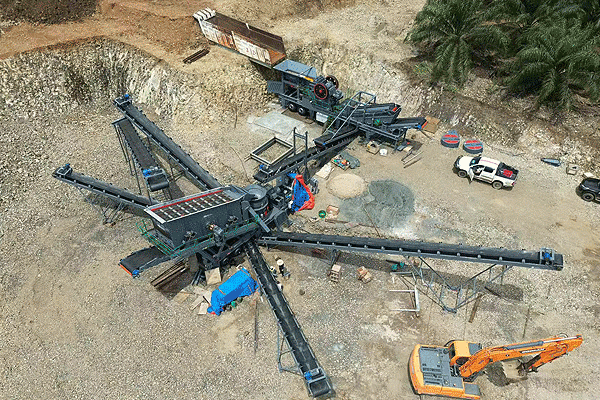

- Mobility Needs: Operations that require moving between sites frequently will benefit greatly from track-mounted units.

It’s important to note that numerous factors influence investment considerations; different operational requirements lead to varying configurations which naturally result in different investment levels.

Conclusion

Jaw crushers remain an indispensable asset for any operation involved in primary size reduction of hard materials like rock concrete asphalt or granite Their simple yet effective crushing principle combined with durable construction