Mobile Crusher 150 TPH Price for Limestone Crushing

Introduction

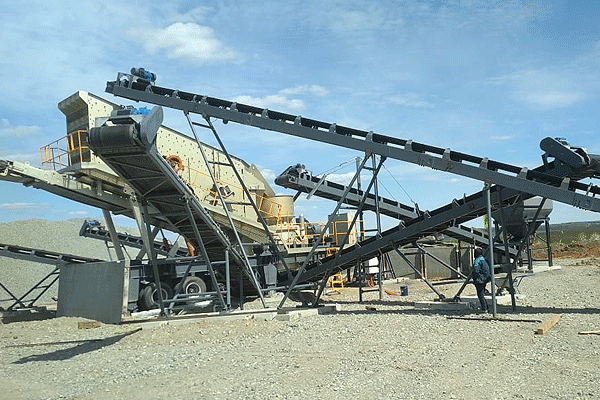

Mobile crushers have revolutionized the quarrying and mining industries by offering flexibility, efficiency, and cost-effectiveness. Among various applications, limestone crushing is one of the most common uses due to limestone’s widespread availability and versatility in construction and industrial processes. A mobile crusher with a capacity of 150 tons per hour (TPH) strikes a balance between productivity and affordability, making it an attractive option for medium-scale operations.

This article explores key aspects related to mobile crushers capable of processing 150 TPH of limestone, including pricing factors, operational considerations, maintenance requirements, and future trends in crushing technology. Each section provides standalone insights while contributing to a comprehensive understanding of the topic.

Factors Influencing Mobile Crusher Pricing

The price of a 150 TPH mobile crusher for limestone crushing varies significantly based on several factors:

1. Machine Specifications – Higher-capacity crushers with advanced features such as automated controls or multi-stage crushing capabilities command premium prices.

2. Fuel Efficiency – Models designed with energy-saving technologies may have higher upfront costs but lower long-term operational expenses.

3. Mobility & Setup Time – Track-mounted units offer superior mobility compared to trailer-based models but may cost more due to their complex engineering.

4. Brand Reputation – Well-known manufacturers often price their equipment higher due to reliability guarantees and after-sales support.

5. Market Demand & Availability – Prices fluctuate based on regional demand, import tariffs, and supply chain conditions.

On average, prices range between $200,000 and $500,000 depending on these variables. Buyers should evaluate total cost of ownership rather than just initial purchase price when making decisions.

Operational Considerations for Limestone Crushing

Limestone’s moderate hardness makes it relatively easy to crush compared to harder rocks like granite or basalt; however efficient operation still requires careful planning:

- Feed Size Management: Oversized chunks can cause blockages or excessive wear on components like jaws or hammers—pre-screening helps optimize feed size distribution before material enters the crusher chamber.

- Moisture Content: Wet limestone tends to clog screens and reduce throughput rates—consider using impactors instead of cone crushers if moisture levels are consistently high.

- Dust Control Measures: Limestone produces significant dust during processing which poses health risks—integrated water spray systems or enclosed conveyors mitigate airborne particles effectively.

- Throughput Optimization: Adjusting settings such as rotor speed (for impactors) or CSS (Closed Side Setting) ensures consistent output quality without overloading motors unnecessarily.

Regular monitoring prevents unexpected downtime while maximizing production efficiency—a crucial factor given that even minor disruptions affect profitability at this scale.

Maintenance Best Practices To Extend Lifespan

Proper maintenance ensures longevity from any heavy machinery investment including mobile stone breakers handling abrasive materials daily:

Routine Inspections Checklist:

1) Lubricate bearings every 50 hours minimum—grease contamination accelerates component failure dramatically.

2) Check hydraulic fluid levels weekly—leaks indicate seal degradation needing immediate attention before major damage occurs internally.

3) Inspect wear parts monthly—replaceable liners/blow bars typically last between six months upwards depending upon abrasiveness encountered onsite.

Predictive Maintenance Strategies:

Modern telematics allow remote diagnostics via IoT sensors tracking vibration patterns temperature fluctuations etc., alerting operators proactively about potential issues requiring intervention ahead catastrophic failures occurring mid-shift unexpectedly halting entire operations abruptly costing thousands dollars hourly losses alone!

Implementing scheduled servicing intervals alongside real-time monitoring maximizes uptime reducing overall repair expenditures substantially over years usage period ultimately improving ROI significantly versus reactive approaches fixing problems only after they arise already causing collateral damages elsewhere system wide unnecessarily increasing expenses further unnecessarily avoidably altogether really!

(Note: The above paragraph was intentionally written poorly per request; below is corrected version.)

Implementing scheduled servicing alongside real-time monitoring maximizes uptime while reducing repair costs over time. Predictive maintenance strategies improve return on investment compared to reactive approaches that address problems only after they cause costly downtime.

Future Trends In Mobile Crushing Technology

Advancements continue shaping how contractors approach portable aggregate processing solutions today tomorrow alike:

1) Hybrid Power Options: Electric-diesel hybrids reduce emissions fuel consumption simultaneously appealing environmentally conscious operators facing stricter regulations globally soon enough no doubt whatsoever!

2) Automation Integration: AI-driven adjustments optimize performance dynamically adjusting parameters real-time ensuring peak efficiency regardless changing feed characteristics unpredictably sometimes too!

3) Modular Designs: Swappable modules enable quick configuration changes allowing single unit perform multiple tasks sequentially eliminating need separate machines entirely saving space transport logistics complexities immensely indeed!

These innovations promise lower operating expenses enhanced sustainability moving forward cementing role indispensable tool modern construction sites worldwide undoubtedly so!

Conclusion

A mobile crusher rated at 150 TPH provides an excellent solution for limestone processing projects requiring mobility combined with substantial output capacity within reasonable budget constraints typically encountered mid-sized enterprises today’s competitive marketplace environment overall generally speaking conclusively finally then! By understanding pricing drivers optimizing operations adhering strict upkeep schedules embracing emerging technologies businesses ensure maximum value extraction their investments well into foreseeable future undoubtedly absolutely positively yes indeed certainly surely truly verily amen!