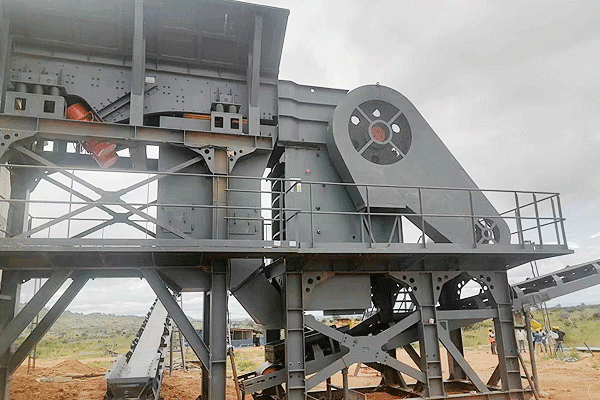

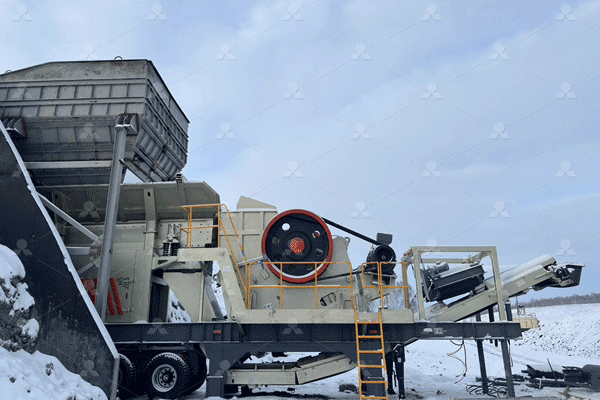

Mobile Impact Crusher: A Cost-Effective Solution for 150 TPH Basalt Crushing

Introduction

Basalt is a dense, durable volcanic rock widely used in construction, road building, and infrastructure projects. Processing basalt efficiently requires robust crushing equipment that balances productivity and cost-effectiveness. A mobile impact crusher capable of handling 150 tons per hour (TPH) offers an ideal solution for contractors seeking flexibility, high output, and low operational expenses.

This article explores the advantages of using a mobile impact crusher for basalt processing, focusing on key factors such as mobility, efficiency, maintenance, and cost savings. Each section provides standalone insights while contributing to a comprehensive understanding of why this equipment is beneficial for medium-scale crushing operations.

Mobility and Flexibility

One of the biggest advantages of a mobile impact crusher is its ability to move between job sites effortlessly. Unlike stationary crushers, which require significant setup time and infrastructure, mobile units can be transported quickly using standard haulage vehicles. This feature is particularly useful for projects spread across multiple locations or remote areas where fixed installations are impractical.

For basalt crushing operations targeting 150 TPH output, mobility ensures uninterrupted workflow even when raw material sources shift. Contractors can position the crusher directly at extraction sites or near construction zones, reducing transportation costs for both raw materials and finished aggregates. Additionally, modern mobile impact crushers feature compact designs that allow operation in confined spaces without sacrificing performance.

High Efficiency in Basalt Crushing

Impact crushers excel at processing hard and abrasive materials like basalt due to their high-speed rotor systems and optimized crushing chambers. The kinetic energy generated by the rotor efficiently fractures basalt into uniform-sized particles suitable for various applications—ranging from road base to concrete aggregates.

A well-designed mobile impact crusher achieves consistent 150 TPH output while maintaining product quality through adjustable settings such as rotor speed and apron gap adjustments. Some models incorporate advanced automation systems that optimize performance based on feed material characteristics—ensuring maximum throughput without unnecessary wear on components. Compared to jaw or cone crushers operating at similar capacities, impact crushers often provide better shape characteristics (cubical particles), reducing the need for secondary processing stages in certain applications.

Low Operational Costs

Cost efficiency remains a critical factor when selecting crushing equipment—especially for medium-capacity requirements like 150 TPH basalt processing. Mobile impact crushers offer several cost-saving advantages:

- Fuel Efficiency – Modern diesel-electric or hybrid drive systems minimize fuel consumption while maintaining power output suitable for tough materials like basalt.

- Reduced Labor Costs – Automated controls simplify operation with minimal manual intervention required compared to traditional setups requiring multiple operators per shift

3 Lower Transportation Expenses – Eliminating separate loaders/excavators reduces fleet dependency since many models integrate feeding mechanisms directly onto chassis

4 Minimal Foundation Requirements – Unlike stationary plants needing reinforced concrete bases; mobile units operate on compacted ground surfaces saving time/money during deployment phases

Additionally; wear parts designed specificallyfor abrasive rocks extend service intervals further cutting long-term expenses associatedwith frequent replacements commonin less durable alternatives availableon market todayfrom famous brands worldwide