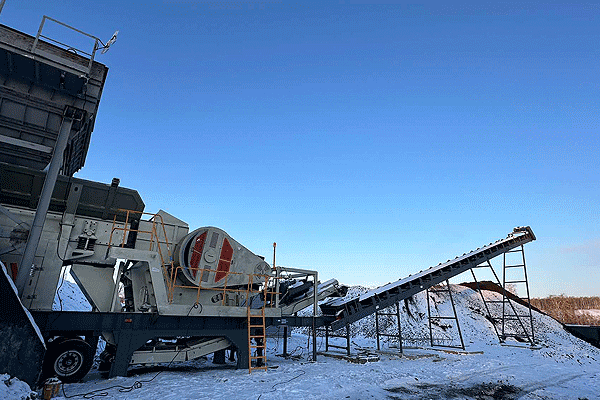

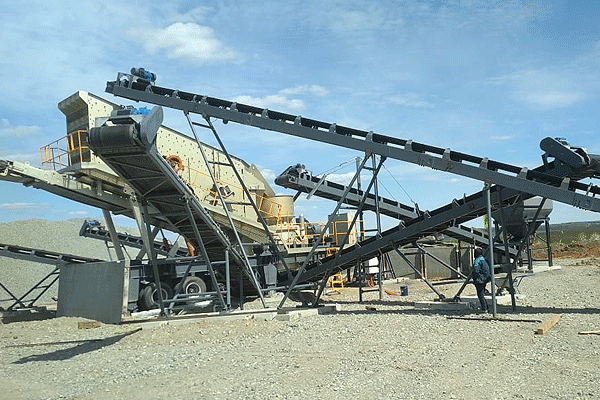

Mobile Quarry Crushing Plants Powered by Diesel Engines

Introduction

Mobile quarry crushing plants have revolutionized the mining and construction industries by offering flexibility, efficiency, and cost-effectiveness. Among the various power options available, diesel-powered units stand out due to their reliability, independence from grid electricity, and ability to operate in remote locations. These plants are designed to process raw materials directly at extraction sites, reducing transportation costs and improving productivity.

This article explores the key aspects of diesel-powered mobile quarry crushing plants, including their advantages, operational considerations, maintenance requirements, environmental impact, and future trends. Each section provides standalone insights for readers seeking specific information.

—

Advantages of Diesel-Powered Mobile Crushing Plants

Diesel engines offer several benefits for mobile quarry crushing operations:

1. Portability & Independence – Unlike electric-powered units that rely on grid connections, diesel-driven crushers can operate anywhere without infrastructure limitations. This makes them ideal for remote quarries or temporary job sites.

2. High Torque & Power Output – Diesel engines provide consistent torque even under heavy loads, ensuring efficient crushing of hard rocks like granite or basalt without performance drops.

3. Quick Setup & Mobility – These plants are mounted on tracks or wheels, allowing rapid relocation between sites with minimal downtime compared to stationary setups.

4. Fuel Availability – Diesel is widely accessible globally, reducing logistical challenges compared to alternative fuels requiring specialized storage or supply chains.

Despite higher fuel costs than electricity in some regions, these advantages make diesel-powered crushers a preferred choice for many operators needing reliable performance in rugged environments.

—

Operational Considerations for Efficiency

To maximize productivity while using diesel-powered mobile crushers:

- Proper Load Management – Overloading the engine increases fuel consumption unnecessarily while underutilization leads to inefficiency—operators should balance feed rates accordingly.

- Optimal Engine RPM Maintenance – Running engines within recommended RPM ranges ensures better fuel economy while maintaining crushing capacity consistently throughout shifts rather than fluctuating speeds unnecessarily wasting energy resources unnecessarily wasted resources unnecessarily wasted resources unnecessarily wasted resources unnecessarily wasted resources unnecessarily wasted resources unnecessarily wasted resources unnecessarily wasted resources unnecessarily wasted resources unnecessarily wasted resources .