The Modern Workhorse: Diesel River Stone Crushers for Granite and Gold Mining

In the demanding fields of construction and mining, the need for robust, efficient, and mobile crushing solutions is paramount. The integration of diesel-powered crushers has revolutionized how operators process tough materials like river stone, granite, and gold-bearing rock. This powerful combination offers a self-sufficient and highly effective method for size reduction directly at the source. This article explores the key features, operational benefits, and specific applications of these versatile machines.

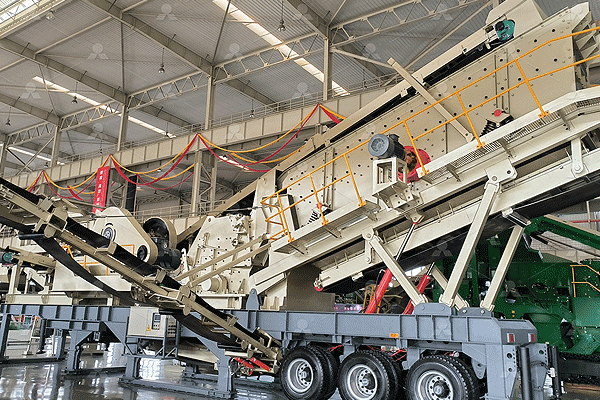

Unmatched Power and Mobility

The core advantage of a diesel-powered rock crusher lies in its exceptional mobility and independence from external power grids. Equipped with a powerful diesel engine, these machines can be transported to and operated in the most remote locations. This is particularly crucial for processing river stone directly from riverbeds or for setting up operations in off-grid gold mining sites where electricity is unavailable or unreliable.

Their design often incorporates a sturdy trailer or a skid-mounted frame, allowing them to be towed to different sites with relative ease. This mobility transforms a static crushing process into a dynamic operation that moves with the project’s progress. Operators are no longer constrained by fixed power sources, enabling them to tackle projects in diverse terrains—from mountainous regions rich in granite to alluvial plains where gold is found. The ability to bring the crusher to the material significantly reduces transportation costs for both raw stone and the final processed aggregate.

Engineered for Extreme Durability

When confronting hard materials like granite or abrasive river stone, durability is non-negotiable. Top-tier crushers are constructed with high-grade materials designed to withstand immense pressure and wear. Critical components such as the jaw plates, liners, and hammers are typically made from high manganese steel or other advanced alloys that offer superior impact resistance and longevity.

The crushing chamber is meticulously designed to optimize the breaking action while minimizing unnecessary wear on parts. For jaw crushers, a deep crushing chamber and an aggressive nip angle ensure that large chunks of granite are gripped firmly and broken efficiently. In hammer crushers or impact models used for slightly less abrasive materials, the rotor dynamics and breaker plate settings are calibrated to deliver maximum fragmentation with each impact. This focus on rugged construction ensures minimal downtime for maintenance and replacement parts, which is a critical factor for continuous mining and quarrying operations.

Versatility Across Multiple Applications

A single diesel crusher can be a highly versatile asset capable of processing a wide range of materials. Its primary application in processing river stone produces clean, well-shaped aggregate highly sought after in construction for concrete and landscaping. When configured for granite—one of the hardest natural stones—it demonstrates its power by producing high-quality base course material, railroad ballast, or architectural aggregate.

In the context of gold mining, these crushers play a vital role in liberating precious metals from host rock. The primary crushing stage breaks down large ore-bearing rocks into smaller fragments that can then be fed into secondary mills or directly into gravity separation systems like sluice boxes. The ability to control the output size is critical here; a finer crush increases the surface area of the ore, potentially improving gold recovery rates during subsequent processing stages.

Key Operational Features for Optimal Performance

To maximize productivity and safety, modern diesel crushers come equipped with several important features. A central electric control system allows operators to start, stop, and monitor the machine’s functions conveniently. Safety features often include automatic shut-off mechanisms in case of overload or mechanical failure, protecting both the machine and personnel.

Another significant consideration is dust suppression. Crushing operations inherently generate dust, which can be an environmental and health hazard. Many models now integrate water spray systems that effectively minimize dust emissions at key transfer points. Furthermore, noise reduction technologies are increasingly being incorporated to make operations more compliant with local regulations and less disruptive in sensitive areas.

Factors Influencing Machine Selection

Choosing the right crusher involves evaluating several project-specific factors rather than focusing on any single metric like price alone because different requirements lead to different configurations which affect overall cost significantly . The hardness , abrasiveness ,and required final product size are primary determinants . A project focused on granite will necessitate a more robust jaw crusher configuration , whereas processing softer river stone might be efficiently handled by an impact crusher .

Production capacity is another major consideration . The required tons-per-hour output will dictate both engine power rating as well as physical size model selected . Finally portability needs must align with machine’s transport dimensions weight ensuring it can be legally easily moved between sites using available equipment . Consulting directly manufacturers providing detailed project specifications ensures receiving optimal machine tailored unique operational demands without overspending unnecessary features capacity .