Portable HST Cone Crusher: Optimal Solution for 150 TPH Basalt Crushing

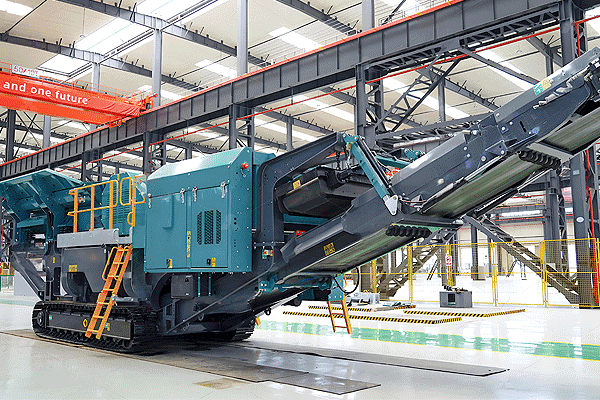

Introduction to Portable HST Cone Crushers

Portable HST cone crushers are advanced crushing machines designed for high efficiency and mobility. These crushers integrate hydraulic, electrical, and automation technologies to deliver superior performance in processing hard materials like basalt. With a capacity of 150 tons per hour (TPH), they are ideal for medium-scale mining and aggregate production. Their portability allows easy relocation between job sites, reducing downtime and transportation costs. The HST design ensures consistent output with minimal wear, making it a cost-effective solution for contractors seeking reliable crushing equipment.

Key Features of the Portable HST Cone Crusher

The portable HST cone crusher stands out due to its robust construction and intelligent features. It incorporates hydraulic adjustment and overload protection, ensuring smooth operation even under heavy loads. The advanced crushing chamber design enhances material reduction efficiency while maintaining low energy consumption. Additionally, automation controls allow operators to monitor performance in real time, optimizing productivity without constant manual adjustments. The compact structure facilitates quick setup, making it suitable for temporary or remote projects where mobility is crucial.

Why Choose This Crusher for Basalt Crushing?

Basalt is an extremely hard and abrasive rock, requiring durable crushing equipment that minimizes wear while maintaining high output. The portable HST cone crusher excels in this application due to its optimized crushing chamber geometry and high-strength components. It efficiently reduces basalt into uniformly sized aggregates suitable for construction and road-building projects. Unlike conventional crushers prone to premature wear, the HST model uses premium materials that extend service life even under continuous operation at 150 TPH capacity.

Cost Efficiency and Competitive Pricing

Investing in a portable HST cone crusher offers long-term cost savings despite the initial capital outlay. Its energy-efficient design lowers operational expenses by reducing power consumption per ton of crushed material. Minimal maintenance requirements further decrease downtime-related costs, ensuring uninterrupted production cycles. Compared to competitors offering similar capacities but inferior durability or higher operating costs, this crusher provides exceptional value without compromising performance—making it an economically sound choice for contractors prioritizing both quality and affordability.

Applications Beyond Basalt Crushing

While highly effective for basalt processing at 150 TPH capacity limits remain flexible enough accommodate various materials including granite limestone river pebbles Its versatility makes useful diverse industries such as mining quarrying recycling Whether producing railway ballast concrete aggregates asphalt mixtures adaptability ensures broad market appeal across different sectors needing reliable mobile crushing solutions

Conclusion: A Smart Investment Choice

The portable HST cone crusher combines mobility durability efficiency ideal solution demanding applications like basalt processing With competitive pricing low operational costs proven reliability represents smart investment businesses seeking maximize productivity minimize expenses Whether used standalone part larger plant setup delivers consistent results toughest conditions making indispensable modern aggregate production operations