Understanding Primary and Secondary Crushers: A Comprehensive Guide

In the world of material processing and aggregate production, crushers play an indispensable role. The journey from raw, oversized rock to precisely sized aggregate is a two-stage process, primarily handled by primary and secondary crushers. Understanding the distinct functions, types, and selection criteria for these machines is fundamental to designing an efficient and productive operation. This guide delves into the core principles of these essential pieces of equipment.

The Fundamental Role of a Primary Crusher

The primary crusher is the first point of contact for raw material extracted from a quarry or mine. Its primary mission is one of brute force: to take the largest rocks and boulders and reduce them to a manageable size for further processing. This machine acts as the workhorse of the operation, handling the toughest and most abrasive materials.

The key characteristic of a primary crusher is its ability to accept very large feed sizes. These machines are designed with robust construction to withstand immense impact and pressure. The reduction ratio—the difference between the input size and the output size—is typically lower in this stage compared to secondary crushing, but the absolute size reduction is massive. The output from a primary crusher, often referred to as “crusher run,” is usually irregular in shape and can range from several inches down to about 6-8 inches in diameter. This material is then conveyed to the next stage of the crushing circuit.

Common Types of Primary Crushing Equipment

Several types of crushers are well-suited for the demanding role of primary crushing, each with its own mechanism and ideal application.

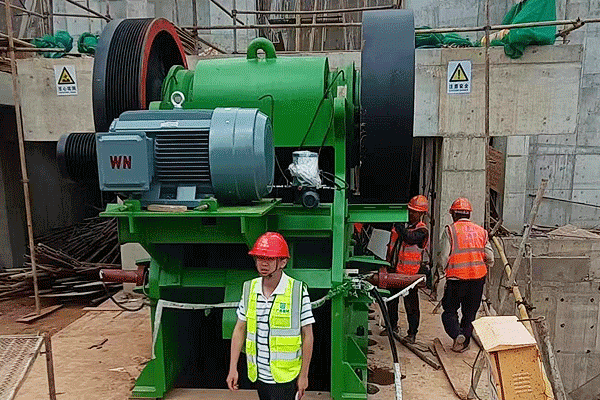

- Jaw Crushers: This is arguably the most common type of primary crusher. It operates using a compressive force mechanism, where a fixed jaw and a moving jaw create a “V” chamber. The rock is crushed as the moving jaw presses it against the stationary one. Jaw crushers are highly reliable, offer high capacity, and are excellent for hard, abrasive materials.

- Gyratory Crushers: Often used in high-capacity mining operations, gyratory crushers feature a long spindle with a crushing head that gyrates within a concave housing. They are exceptionally efficient and can handle very large feed sizes, typically offering higher throughput than jaw crushers of comparable size.

- Impact Crushers: While less common for very hard rock in the primary stage, horizontal shaft impactors can be used as primary crushers for softer, non-abrasive materials like limestone or recycled concrete. They utilize high-speed impact rather than compression to break rock.

The Purpose and Function of Secondary Crushers

If the primary crusher’s job is coarse reduction, the secondary crusher’s role is refinement. It takes the pre-crushed material from the primary stage and processes it further to achieve specific product specifications. The focus shifts from raw size reduction to shaping and producing precisely graded end products.

Secondary crushing aims for a higher reduction ratio than the primary stage, creating smaller, more uniform aggregate sizes suitable for applications like concrete asphalt or road base. This stage also plays a crucial role in improving the particle shape (cubicity), which is vital for the quality and strength of final products like ready-mix concrete.

Popular Configurations for Secondary Crushing

Secondary crushers employ different breaking actions to achieve their goals of sizing and shaping.

- Cone Crushers: These are the dominant choice for secondary crushing, especially for hard and abrasive materials. They work by compressing rock between a rotating mantle and a stationary concave liner. Cone crushers are renowned for their efficiency, consistent product gradation, and ability to produce well-shaped particles.

- Impact Crushers (Horizontal Shaft Impactors): Impact crushers excel in secondary applications where producing a high-quality cubical product is paramount. They “throw” the rock against hardened aprons or anvils using high-speed rotors with blow bars. This makes them ideal for softer stones and recycling applications.

- Vertical Shaft Impactors (VSI): A specialized type of impact crusher, VSIs are considered tertiary crushers but often function in a secondary role for shaping. They use a high-speed rotor to fling material against a crushing chamber, creating excellent cubical shape through rock-on-rock or rock-on-anvil breaking.

Key Factors in Selecting Your Crushing Circuit

Choosing between different types of primary and secondary crushers depends on several critical factors related to your specific project.

The most important consideration is undoubtedly the material characteristics. This includes its hardness, abrasiveness, stickiness, and initial feed size. Hard, abrasive granite demands robust jaw or gyratory primaries paired with cone secondaries; softer limestone may allow for different configurations including impactors at both stages.

The required final product specifications—such as particle size distribution (gradation) and shape—are equally vital. If producing cubical aggregate for asphalt is critical an impact crusher might be selected over other options despite potentially higher wear costs on abrasive material.

Furthermore operational factors like desired production capacity plant layout space constraints maintenance requirements availability all influence decision-making process significantly affecting overall efficiency profitability operation itself Many factors influence final investment including desired capacity machine configuration specific features chosen reputable brands generally command premium due their proven reliability after-sales support Ultimately different requirements lead different configurations which turn lead varying investment levels