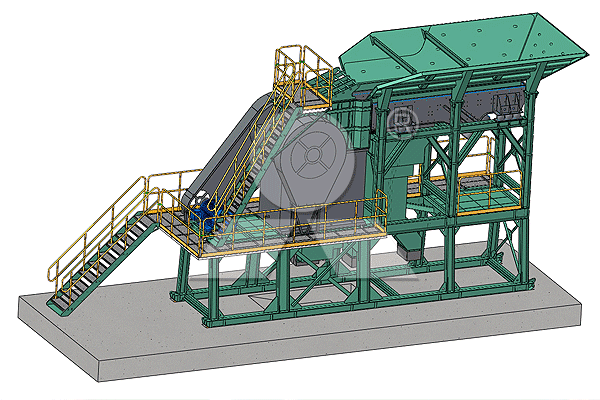

SMP modular crushing production line of Liming Heavy Industry is a highly convenient modular and fast production line for sand and gravel crushing. Based on the applications of fixed and mobile production lines, it is lunched by pre-designed crushing and screening modules and on-site layout planning. It maximizes fast delivery and quick assembly. The delivery and commissioning times is 30%-40% faster than traditional production lines. Additionally, it boasts high overall reliability and conforms to relevant international safety design standards. It also eliminates the need for large-scale concrete foundations, making it more environmentally friendly.

Applications: quarry, metallurgical mines, building materials, highways, railways, water conservancy, chemical industry and other industries are mainly used for crushing, screening, shaping, sand making and construction waste for various stones.

Specifications – Technical DataPrinciple

| Standard factory | Maximum feeding size (MM) |

Final product capacity (T/H) |

Crushing series |

Granular index |

Modular configuration | Total power | ||||||

| 0/25 | 0/31.5 | 0/40 | Primary crushing module |

Two and third -stage crushing modules |

Screening module | |||||||

| SMP75H | 425 | 70 | 80 | 95 | 2 | ●● | MPJ75 | MPC75 | – | MPS1544 | – | 227.6 |

| SMP100H | 500 | 85 | 95 | 105 | 2 | ●● | MPJ100 | MPC100 | – | MPS1864 | – | 299.6 |

| SMP200H | 630 | 180 | 200 | 200 | 2 | ●● | MPJ200 | MPC300 | – | MPS2164 | – | 480.2 |

| SMP200HP | 630 | 180 | 200 | 200 | 2 | ●●● | MPJ200 | MPC160 | MPC160 | MPS2164 | – | 533.4 |

| SMP200HV | 630 | 180 | 195 | 240 | 2 | ●●●● | MPJ200 | MPC300 | MPV9526 | MPS1863 | MPS1863 | 808.35 |

| SMP300H | 720 | 280 | 300 | 320 | 2 | ●● | MPJ300 | MPC315 | – | MPS2464 | – | 652.2 |

| SMP300HE | 720 | 280 | 300 | 320 | 2 | ●●○ | MPJ300 | MPC500 | – | MPS2464 | – | 751.7 |

| SMP300HV | 720 | 350 | 350 | 350 | 3 | ●●●● | MPJ300 | MPC315 | MPV1040 | MPS2163 | MPS2163 | 1124.55 |

| SMP450HV | 800 | 400 | 400 | 425 | 3 | ●●○ | MPJ450 | MPC250 | MPC315 | MPS2164 | MPS2164 | 971.7 |

| SMP1005S | 500 | 90 | 100 | 120 | 2 | ●●● | MPJ100 | MPF1214 | – | MPS1864 | – | 326.6 |

| SMP200S | 630 | 180 | 200 | 200 | 2 | ●●● | MPJ200 | MPF1213CI | – | MPS2164 | – | 433.7 |

| SMP300S | 720 | 240 | 270 | 300 | 2 | ●●● | MPJ300 | MPF1315CI | – | MPS2464 | – | 567.7 |

Note:

1. The product capacity listed in this table is calculated based on the proportion of 1.6T/m3. The production capacity is affected by various factors, such as the nature of the material, the feed, output and other working conditions, the amount of water content, the density and the crush ability and so on, so the data in the table will change depending on the specific situation;

2. The calculation of the capacity in the table adopts process of ‘crushing first and then screening’

3. The production capacity in the table is not include the finished product that is sieved under the sieve;

4. The total power in the table is the total power of the host equipment, without the power of accessories such as belt conveyor, iron removal, etc.

5. The total weight in the table is the total weight of the host equipment, which does not contain the total weight of subsidiary equipment such as steel structures, belt conveyor;

6. The final explanation right of the above standards definition is reserved by Henan LIMING Heavy Industry Science and Technology Co. LTD. The technical parameters designed in this article are for reference only. Any change or upgrades of technical data shall not be advised additionally.

7. The above is a standard modular production line. If customers have special needs, please contact with us directly.