One of the representative Stone Crusher Unit is M/s. Sadbhav Quarry Works, Gujarat

i) Basic Details

This unit is located in the Tulsigam village of Vadodara district in Gujarat. The raw material is Black Trap stone which comes from the company’s own open cast mines located nearby. The units are in operation for 3 shifts/day. The basic details of the unit are given below.

Type & Size of Primary Crusher : Jaw (36” X 24”), 1 No

Type & Size of Secondary Crusher : Jaw (30” X 15”), 2 Nos.

Type & Size of Tertiary Crusher : Jaw (30” X 9” & 30” X 6”), 2 Nos.

Crushing Capacity: : 2200 T/Day(>100 TPH)

Type & No. of Screens : Vibratory, 2 No. (Prim. & Sec.)

Type of Raw Material : Black trap stone from open-cast mines

ii) Products

Size in mm Local name

+ 40 Metal

+ 20 Kappchi

10-20 Grit

iii) Process Description of the stone crusher unit

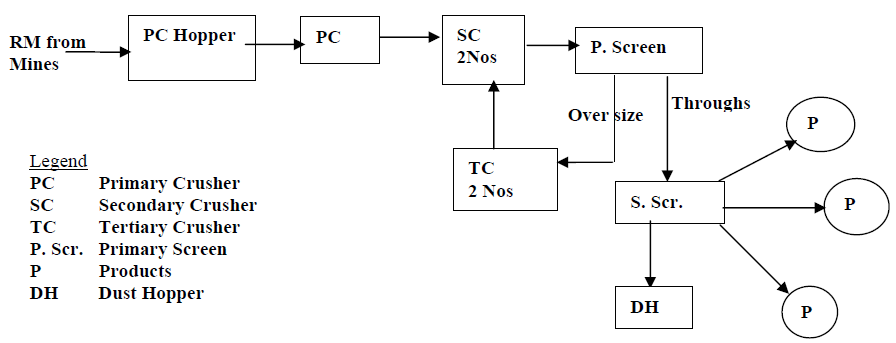

The raw material (Black Stone) from the mines consists of stones of various sizes from fines to large boulders. It is unloaded into the primary crusher hopper. The material is fed to the primary crusher via feeder. After primary crushing the material is conveyed to the hopper of the secondary crusher by belt conveyor. The material is further crushed and transferred to the screen for first screening. The ‘oversize’ from this screen goes to the tertiary crusher for crushing. The crushed material goes to the primary screen via the same belt conveyor (conveyor used to transfer the secondary crusher material). The ‘throughs’ from the first screen goes to the secondary screen for further screening and separation of different products and Dust. The dust is stored in hopper and directly unloaded into the truck. The products are discharged from the screen via conveyor belts to various stockpiles. From stockpiles the product is loaded into the trucks with the help of loaders and delivered at the point of use.

iv) Process Flow Diagram of stone crusher unit.