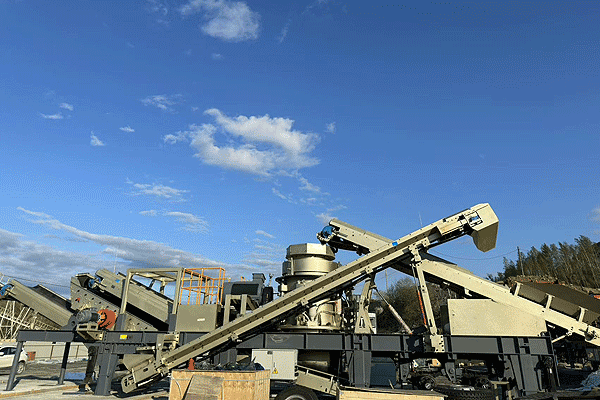

Small Mobile Jaw Crusher for 80-100 TPH Gold Ore Processing

Introduction

A small mobile jaw crusher is an efficient and versatile machine designed for processing gold ore with a capacity of 80-100 tons per hour (TPH). These compact crushers are ideal for small to medium-scale mining operations, offering mobility, ease of setup, and reliable performance. Unlike stationary crushers, mobile units can be transported directly to mining sites, reducing material handling costs and improving operational efficiency.

Gold ore processing requires robust equipment capable of handling hard rock while maintaining consistent output. A well-designed mobile jaw crusher ensures high crushing ratios, adjustable discharge settings, and low maintenance requirements—making it a practical choice for gold miners seeking cost-effective solutions.

Key Features of Mobile Jaw Crushers

Small mobile jaw crushers designed for 80-100 TPH gold ore crushing typically include several essential features:

- Compact Design: Their small footprint allows operation in confined spaces while maintaining high productivity.

- Diesel or Electric Power Options: Depending on site conditions, operators can choose between diesel engines or electric motors for power supply.

- Adjustable Jaw Settings: The ability to modify discharge sizes ensures optimal crushing efficiency for different ore grades.

- Integrated Feeders and Screens: Some models come with pre-screening capabilities to remove fines before crushing, improving overall efficiency.

- Easy Relocation: Mounted on tracks or wheels, these crushers can be quickly moved between sites without disassembly.

These features make mobile jaw crushers highly adaptable to various mining environments while maintaining consistent throughput.

Advantages Over Stationary Crushers

Compared to stationary crushing plants, small mobile jaw crushers offer significant advantages:

- Lower Transportation Costs: Since the crusher moves directly to the material source, haulage expenses are minimized.

- Reduced Setup Time: Mobile units require minimal foundation work and can be operational within hours of arrival at the site.

- Flexibility in Operation: They can process multiple types of ore without requiring major reconfigurations.

- Better Suitability for Remote Sites: In areas lacking infrastructure, self-powered mobile crushers eliminate dependence on external power sources.

For gold miners working in dynamic environments where deposit locations change frequently, mobility translates into higher profitability and operational agility.

Maintenance and Durability Considerations

Maintaining a small mobile jaw crusher involves routine checks to ensure longevity:

- Regularly inspect wear parts such as jaw plates and toggle seats to prevent unexpected downtime.

- Lubricate bearings and moving components according to manufacturer guidelines to minimize friction-related failures.

- Monitor hydraulic systems (if applicable) for leaks or pressure inconsistencies that could affect performance.