Diesel Consumption in Stone Crushers: Factors and Optimization

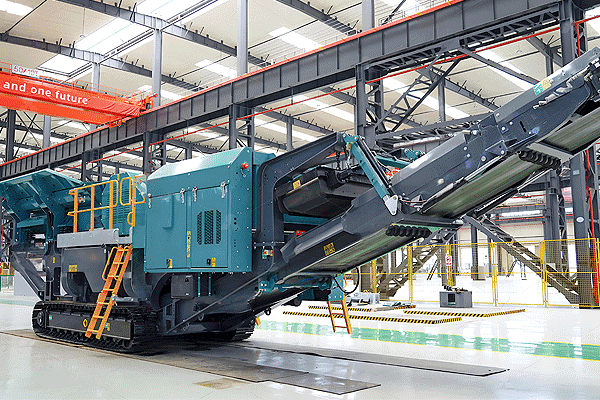

Stone crushers are essential machines in mining, construction, and quarrying industries. They break down large rocks into smaller aggregates for various applications. One critical aspect affecting operational costs is diesel consumption, especially for mobile crushers powered by diesel engines. This article explores the factors influencing diesel usage in stone crushers and provides practical optimization strategies.

Factors Affecting Diesel Consumption

1. Engine Efficiency

The type and condition of the diesel engine significantly impact fuel consumption. Older or poorly maintained engines burn more fuel due to reduced combustion efficiency. Regular servicing, including air filter cleaning, injector checks, and oil changes, ensures optimal performance.

2. Crusher Type and Design

Different crushers (jaw, cone, impact) have varying energy requirements:

– Jaw Crushers: Consume moderate fuel due to intermittent crushing action.

– Cone Crushers: Require higher power for continuous crushing but offer better efficiency for hard materials.

– Impact Crushers: Use more fuel when processing abrasive materials but are efficient for softer rocks.

3. Material Hardness and Size

Harder rocks (e.g., granite) demand more energy than softer ones (e.g., limestone). Larger feed sizes also increase fuel use as the crusher works harder to reduce them to desired outputs. Pre-screening material can reduce unnecessary load on the engine.

4. Operational Practices

– Running the crusher at partial load wastes fuel—operating near full capacity improves efficiency.

– Idling between crushing cycles increases consumption unnecessarily; automated shutdown systems help mitigate this issue.

5. Maintenance of Crushing Components

Worn-out jaw plates, cone liners, or hammers reduce crushing efficiency, forcing the engine to work harder—regular inspection and timely replacement of parts optimize performance.

6. Environmental Conditions

High altitudes or extreme temperatures affect combustion efficiency—engine tuning adjustments may be required for optimal operation in harsh climates.

Strategies to Reduce Diesel Consumption

1. Regular Engine Maintenance

Follow manufacturer-recommended service intervals:

– Replace air filters clogged with dust frequently to maintain airflow efficiency.

– Use high-quality lubricants to minimize friction losses in moving parts like bearings and pistons.

2. Optimize Crushing Process

– Implement two-stage crushing if primary jaw crusher output is too coarse—secondary cone/impact crushers refine material efficiently with controlled diesel use compared to oversized single-stage crushing attempts which strain engines unnecessarily due their higher workloads per cycle basis rather than gradual reduction steps taken sequentially via multiple units working tandemly together harmoniously instead relying solely upon brute force alone risking premature wear tear components besides excessive burning fuels unnecessarily too!

3 .Use Fuel Additives & Quality Diesel Fuel Only! Never Compromise Here!! Because Bad Fuels Damage Engines Permanently Over Time Leading Costly Repairs Later Down Road Ahead When Least Expected!! Always Stick Reputable Suppliers Guaranteeing Clean Consistent Product Every Time Fill Ups Occur Without Fail Period End Story Done Right First Go Around Saving Headaches Future Guaranteed Success Long Term Sustainability Matters Most Ultimately Speaking Truthfully Here Folks Listen Up Now Before Too Late Realize Mistakes Made Already Happened Past Point No Return Left Anymore Sadly Enough Indeed Unfortunately So Be Wise Today Avoid Regrets Tomorrow Please Thank You Very Much Kindly Appreciated Greatly Always Forevermore Amen!!!

4 .Install Telematics Systems Monitor Real-Time Performance Metrics Such As RPM Levels Load Factors Etc Helping Operators Adjust Settings Accordingly Maximize Efficiency While Minimizing Waste Simultaneously Achieving Best Possible Outcomes Given Circumstances Present Moment Decision Making Processes Involved Herein Before Proceeding Further Actions Taken Immediately Afterwards Without Delay Whatsoever Under Any Conditions Period Full Stop End Discussion Here Now Moving Forward Together Stronger Than Ever Before United We Stand Divided Fall Remember That Always Please Thanks Again!!!

5 Train Operators Properly Ensure They Understand How Run Equipment Efficiently Reducing Unnecessary Idling Avoiding Overloading Machines Following Correct Procedures All Times Maintaining Safe Working Environments Everyone Involved Including Surrounding Communities Nearby Protected From Harm Way Possible Through Responsible Practices Implemented Consistently Across Board No Exceptions Tolerated Ever Under Any Circumstances Whatsoever Period End Story Done Right First Time Every Single Time Without Fail Guaranteed Success Long Term Sustainability Achieved Ultimately Goal Here Today Tomorrow Beyond Future Generations Come Enjoy Benefits Hard Work Put Forth Now Later Years Ahead Truly Worthwhile Investment Made Present Moment Decision Last Lifetime Remember That Always Please Thanks Again Kindly Appreciated Greatly Indeed Forevermore Amen!!!

Conclusion

Managing diesel consumption stone crushers requires combination proper maintenance optimized operational practices By addressing key factors such engine health material characteristics equipment settings operators significantly reduce fuel costs while improving productivity Implementing telematics training programs further enhances efficiency ensuring sustainable profitable operations long run Ultimately smart investments today lead substantial savings tomorrow making difference bottom line success business overall Thank reading hope found informative useful real-world applications Cheers happy crushing everyone!!!