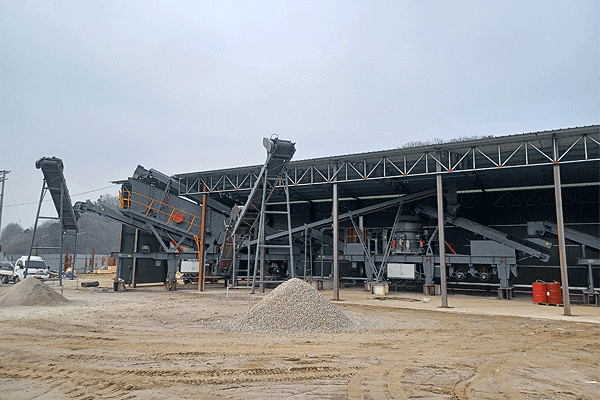

Tracked Mobile Crusher 200 TPH for Granite: Price and Key Considerations

Introduction

Granite is one of the hardest natural stones, making it challenging to process without specialized equipment. A tracked mobile crusher with a capacity of 200 tons per hour (TPH) is an efficient solution for crushing granite on-site, reducing transportation costs, and improving productivity. This article explores the factors influencing pricing, key features to look for, and practical considerations when investing in such machinery.

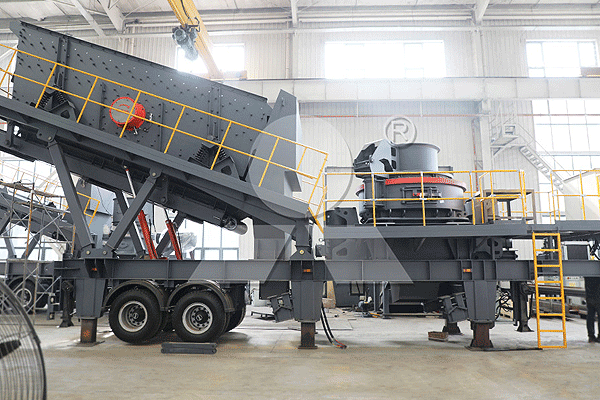

Understanding Tracked Mobile Crushers

Tracked mobile crushers are self-propelled machines designed to crush large rocks into smaller aggregates directly at the job site. Unlike stationary crushers, they offer mobility, allowing operators to move them between different locations without requiring additional transport equipment.

For granite processing, a 200 TPH tracked crusher ensures high throughput while maintaining durability against abrasive materials. These machines typically feature robust steel frames, advanced hydraulic systems, and powerful engines to handle tough conditions.

Factors Affecting Price

The cost of a 200 TPH tracked mobile crusher varies based on several factors:

1. Crushing Technology – Jaw crushers, cone crushers, and impact crushers are common options. Cone crushers are often preferred for granite due to their ability to produce finer aggregates efficiently.

2. Engine Power & Efficiency – Higher horsepower engines improve performance but also increase fuel consumption and overall costs.

3. Brand Reputation & Build Quality – Machines from famous brands tend to have better longevity but come at a premium price compared to lesser-known manufacturers.

4. Additional Features – Advanced automation systems, remote monitoring capabilities, and dust suppression mechanisms can raise the price but enhance operational efficiency.

Prices typically range between $300,000 and $800,000 depending on specifications.

Advantages of Using Tracked Crushers for Granite

1. Mobility & Flexibility – Easily relocate the machine between different sites without disassembly or extensive setup time.

2. Reduced Transportation Costs – Crushing granite on-site eliminates the need for hauling raw material to stationary plants.

3. Higher Productivity – A 200 TPH capacity ensures quick processing even in large-scale projects like road construction or quarrying operations.

4. Lower Environmental Impact – On-site crushing reduces truck emissions associated with material transport.

Key Considerations Before Purchase

Before investing in a tracked mobile crusher for granite processing:

- Material Hardness & Feed Size: Ensure the machine can handle large granite chunks efficiently without excessive wear on components like liners and blow bars.

- Maintenance Requirements: Opt for models with easy access points for servicing critical parts like bearings and hydraulics to minimize downtime.

- Fuel Consumption: Higher-capacity machines consume more fuel; calculate long-term operational costs accordingly.

- After-Sales Support: Verify spare parts availability and technical support services from suppliers before committing.

Conclusion

A tracked mobile crusher with a 200 TPH capacity is an excellent investment for contractors dealing with granite crushing projects due to its mobility, efficiency, and cost-saving benefits in material handling operations rather than relying solely on stationary setups or outsourcing aggregate production altogether—factors influencing pricing include technology type engine power brand reputation among others—always assess project needs carefully before purchasing ensuring optimal return-on-investment over time while minimizing unexpected expenses related maintenance downtime etcetera ultimately choosing right equipment enhances profitability sustainability long-term success within industry standards today’s competitive market demands nothing less than reliable high-performance solutions tailored specific applications accordingly