What Is Jaw Crusher Used For?

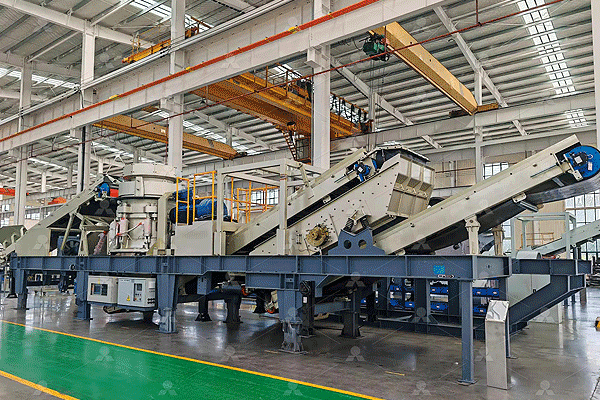

Introduction to Jaw Crushers

A jaw crusher is a primary crushing machine widely used in mining, construction, and recycling industries. It operates by compressing materials between two plates—one fixed and one moving—to break large rocks or ores into smaller pieces. Known for its efficiency and durability, this equipment is essential in various material processing applications. Its simple design makes it easy to maintain, while its versatility allows it to handle hard and abrasive materials effectively.

Working Principle of Jaw Crushers

The jaw crusher functions through a mechanical process called compression crushing. The movable jaw exerts force on the rock or ore by pressing it against the stationary jaw plate. As the material enters the crushing chamber, it gets progressively smaller until it reaches the desired size and exits through the discharge opening. The gap between the jaws can be adjusted to control the output size, making jaw crushers suitable for different stages of crushing operations.

Common Applications

Jaw crushers are primarily used for:

- Primary Crushing: Breaking down large rocks extracted from quarries into manageable sizes for further processing.

- Recycling: Crushing concrete, bricks, and demolition waste for reuse in construction projects.

- Mining: Reducing ore sizes before refining processes such as grinding or leaching.

- Aggregate Production: Creating gravel and sand for road construction and concrete manufacturing.

Their ability to handle tough materials makes them indispensable in heavy-duty industries.

Advantages of Using Jaw Crushers

Several benefits make jaw crushers a preferred choice:

- High Efficiency: Capable of processing large volumes quickly with minimal energy consumption.

- Durability: Built with robust materials to withstand harsh working conditions.

- Versatility: Suitable for various materials, including granite, basalt, limestone, and recycled concrete.

- Easy Maintenance: Simple mechanical structure reduces downtime during repairs or part replacements.

These advantages contribute to their widespread adoption across multiple sectors.

Key Considerations When Choosing a Jaw Crusher

Before selecting a jaw crusher, evaluate factors such as:

- Material Hardness: Ensure the machine can handle the abrasiveness of your target material.

- Feed Size: Match the crusher’s inlet dimensions with your raw material size requirements.

- Output Requirements: Adjustable settings allow customization based on final product specifications.

- Power Consumption: Balance operational costs with performance efficiency for long-term savings.

Proper selection ensures optimal productivity and cost-effectiveness in crushing operations.

Conclusion

Jaw crushers play a critical role in reducing large rocks into smaller fragments across industries like mining, construction, and recycling. Their robust design, operational efficiency, and adaptability make them indispensable machinery for primary crushing tasks. By understanding their working principles and applications, businesses can maximize their benefits while ensuring sustainable material processing practices.