Selecting the Optimal Secondary Stone Crusher for Your Operation

The secondary crushing stage is a critical phase in any aggregate or mining operation. It serves as the bridge between primary size reduction and final product shaping. The primary crusher creates coarse material, but it is the secondary crusher that refines this into specific, marketable sizes. Choosing the right machine for this stage directly impacts overall plant efficiency, product quality, and operational costs. This article explores the most effective types of secondary crushers, their unique advantages, and key selection criteria to guide your investment.

Understanding the Role of Secondary Crushing

Secondary crushing is fundamentally about control and precision. Its primary objective is to take the irregularly sized output from the jaw crusher—typically ranging from 6 to 10 inches—and reduce it further to a more consistent aggregate between 1 and 3 inches. This process is not merely about making rocks smaller; it is about shaping them correctly and liberating valuable minerals locked within the stone. A well-chosen secondary crusher will produce a cubical product, which is highly desirable for construction applications like concrete and asphalt, as it provides better compaction and strength. Furthermore, by achieving a more uniform size distribution, it reduces the load and wear on subsequent tertiary crushers or screens, optimizing the entire production line’s throughput and longevity.

Top Contenders for Secondary Crushing Applications

Several types of crushers excel in secondary roles, each with distinct crushing principles suited for different materials and product goals.

1. Cone Crushers: The Workhorse for Hard Abrasive Rock

Cone crushers are arguably the most common choice for secondary crushing, especially when processing hard and abrasive materials like granite, basalt, and quartzite. They operate by compressing rock between a gyrating mantle and a stationary concave liner. This compression-breaking action is highly efficient for hard rock and produces a consistent, well-graded product with a good particle shape.

- Key Advantages: Their robust construction allows for high-capacity processing of very hard materials. Modern models often come with advanced hydraulic systems that allow for easy adjustment of the closed-side setting (CSS) during operation and provide automatic protection against tramp metal or uncrushable material.

2. Impact Crushers: Masters of Shape in Soft to Medium Materials

Impact crushers utilize high-speed rotors with hammers or blow bars that throw rock against hardened impact plates. This impact force causes the rock to break along its natural fissures, resulting in a highly cubical product. They are exceptionally effective for processing softer to medium-hardness materials such as limestone, recycled concrete, and asphalt.

- Key Advantages: The primary benefit is their superior ability to create a well-shaped, cubical end product without excessive flaky or elongated pieces. They also offer excellent flexibility, as adjusting the rotor speed and the gap between the rotor and impact aprons can significantly alter the final product’s gradation without needing to change physical components.

3. Horizontal Shaft Impactors (HSI): A Versatile Alternative

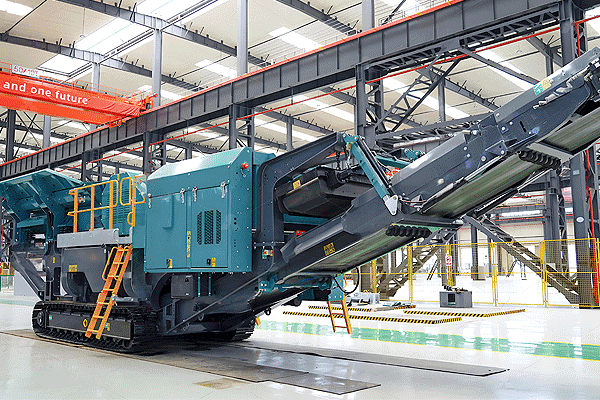

While often categorized under impact crushers, Horizontal Shaft Impactors deserve specific mention for their versatility in secondary roles. They function similarly to standard impact crushers but are often designed for higher capacity applications.

- Key Advantages: HSIs are known for their high reduction ratios, often capable of taking larger feed sizes from the primary stage than some cone crushers. They are excellent all-around performers for a mix of materials and are particularly adept at handling recycled aggregate.

Comparative Analysis: Making an Informed Choice

The decision between a cone crusher and an impact-style crusher hinges on two main factors: material characteristics and desired product shape.

- For Hardness vs. Shape: If your primary material is very hard and abrasive (e.g., granite), a cone crusher will typically offer lower wear costs per ton and greater operational stability over time.

- For Product Cubicity: If your market demands a highly cubical product from softer stone (e.g., limestone), an impact crusher or HSI will be more effective at achieving this shape specification.

- Operational Considerations: Cone crushers generally require more maintenance on wear parts like mantles and concaves but consume less power per ton crushed on hard rock.

- Flexibility: Impact crushers offer greater flexibility in adjusting product size quickly but may have higher wear costs when processing abrasive materials.

Key Factors Influencing Your Final Selection

Beyond just machine type, several other critical factors must be considered:

- Material Properties: The abrasiveness index, hardness (compressive strength), moisture content, and silica content of your feed material are paramount.

- Production Requirements: Define your required hourly tonnage (capacity) precisely.

- Final Product Specifications: Know exactly what sizes and particle shapes your customers demand.

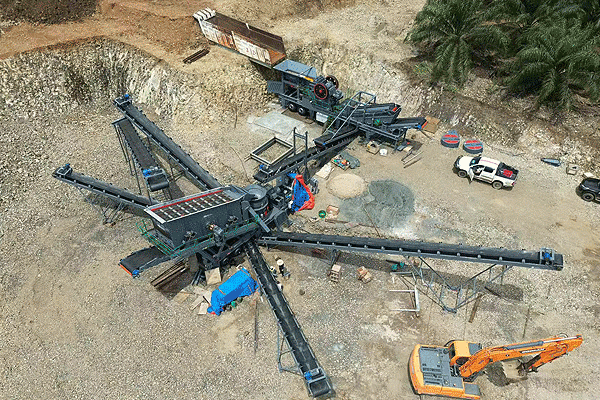

- Site-Specific Constraints: Consider available space, mobility needs (stationary vs. portable setup), power availability,and long-term operational goals.

When considering investment value,the final cost is influenced by many factors.Different requirements lead to different configurations,and consequently,the price varies.It’s crucial to evaluate not just initial capital outlay but also long-term operating expenses related to wear parts,labor,and energy consumption.Consulting with industry experts can provide tailored advice based on these variables.A thorough analysis ensures you select equipment that delivers optimal performance over its entire lifecycle,making it truly cost-effective rather than simply inexpensive upfront