The Difference Between Cone Crusher and Jaw Crusher

Introduction

Cone crushers and jaw crushers are two of the most widely used crushing machines in mining and construction industries. While both are designed to reduce large rocks into smaller pieces, they operate differently and serve distinct purposes. Understanding their differences helps in selecting the right equipment for specific applications.

Working Principle

Jaw Crusher:

A jaw crusher operates by compressing material between two plates—a fixed jaw and a movable jaw. The movable jaw exerts force on the rock, breaking it into smaller fragments through repeated compression cycles. This mechanism is ideal for primary crushing, where large materials need initial size reduction.

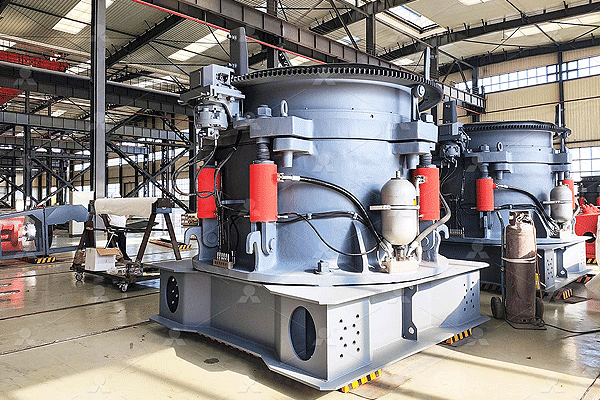

Cone Crusher:

A cone crusher crushes material between a rotating mantle and a stationary concave liner. The mantle gyrates within the concave, squeezing rocks against its walls until they break apart. Cone crushers are typically used for secondary or tertiary crushing, producing finer and more uniform particles compared to jaw crushers.

Crushing Efficiency and Output Shape

Jaw Crusher:

Jaw crushers produce coarser output with irregularly shaped particles due to their compressive action. They excel at handling hard, abrasive materials but may generate more fines when processing softer rocks. Their simplicity makes them reliable but less precise in controlling particle size distribution.

Cone Crusher:

Cone crushers offer better control over particle shape and size due to their interparticle crushing mechanism (rock-on-rock crushing). They produce more cubical-shaped aggregates, making them preferable for high-quality final products in asphalt or concrete production. However, they consume more power than jaw crushers for similar tasks.

Applications

Jaw Crusher Applications:

- Primary crushing of hard materials (e.g., granite, basalt)

- Mining operations requiring high throughput

- Demolition debris processing

- Quarrying operations where large feed sizes are common

Cone Crusher Applications:

- Secondary or tertiary crushing stages

- Producing finely crushed aggregates for construction

- Mineral processing plants requiring precise sizing

- Recycling operations needing uniform output

Maintenance Requirements

Jaw Crusher Maintenance:

Jaw crushers have fewer moving parts than cone crushers, making maintenance relatively straightforward. Common wear parts include toggle plates, cheek plates, and jaws—all easily replaceable without extensive downtime. Lubrication points are minimal compared to cone models.

Cone Crusher Maintenance:

Cone crushers require more frequent inspections due to complex internal mechanisms like eccentric assemblies and hydraulic systems. Wear parts such as mantles and concaves need regular replacement depending on abrasiveness of processed material—adding operational costs over time if neglected properly maintained upkeep reduces unexpected failures significantly prolonging lifespan machine’s lifespan significantly prolonging lifespan machine’s lifespan significantly prolonging lifespan machine’s lifespan significantly prolonging lifespan machine’s lifespan significantly prolonging lifespan machine’s lifespan significantly prolonging lifespan machine’s lifespan significantly prolonging lifespan machine’s lifespan significantly prolonging lifespan machine’s lifespan significantly prolonging lifespan machine’s lifespansignificantlyprolongingspanmachine’slifespansignificantlyprolongingspanmachine’slifespansignificantlyprolongingspanmachine’slifespansignificantlyprolongingspanmachine’slifespansignificantlyprolongingspanmachine’slifespansignificantlyprolongingspanmachine’slifespansignificantlyprolongingspanmachine’slifespansignificantlyprolongingspanmachine’slifespan