Understanding the Three Stages of Rock Crushing: Primary, Secondary, and Tertiary

In the world of aggregate production and mineral processing, efficiency is paramount. Reducing raw, blasted rock into precisely sized aggregate involves a multi-stage process that is both an art and a science. This process is systematically divided into three key phases: primary, secondary, and tertiary crushing. Each stage serves a distinct purpose and employs specific types of machinery to progressively refine the material. Understanding the role and function of each stage is crucial for optimizing operations, improving final product quality, and managing operational costs.

The Primary Crushing Stage: The First Line of Reduction

The primary crushing stage is the initial and most robust step in the size reduction process. Its core objective is to take large run-of-mine (ROM) material, which can be several feet in diameter, and break it down into a more manageable size for subsequent processing stages. This phase handles the largest and hardest rocks, requiring equipment built for immense strength and durability rather than for producing finely shaped particles.

Machinery used in primary crushing is designed to accept large feed sizes and apply massive force to fracture the material. The most common types of crushers in this stage are jaw crushers and gyratory crushers. These machines function by compressing the rock between a stationary surface and a moving surface. The output from the primary crusher, often referred to as the discharge, typically ranges between 6 to 10 inches in size. This product is not yet ready for final use but is perfectly prepared to be fed into the secondary crushing circuit. The efficiency of this first stage sets the foundation for the entire downstream process.

The Role of Secondary Crushing: Refining for Consistency

Following primary reduction, the secondary crushing stage takes over with the goal of further reducing the rock size while also beginning to improve the shape of the final product. If primary crushing is about brute force, secondary crushing introduces more precision. This stage processes the output from the primary crusher, breaking it down further to a size usually between 1 inch and 3 inches.

The equipment selected for secondary crushing often differs from that used in the primary stage. Cone crushers are frequently employed here due to their ability to handle hard and abrasive materials efficiently while providing a more controlled particle shape. Impact crushers are another popular choice, especially when a better cubical product is desired from slightly less abrasive rock. The key outcome of secondary crushing is a more consistent and uniform material size distribution. This consistency is vital for ensuring high performance in applications like road base or as feed for the final tertiary stage.

Tertiary Crushing: Achieving Precision in Final Product Specification

The tertiary crushing stage represents the final phase of particle size reduction. Its purpose is not merely to make small rocks smaller but to produce precise, high-quality aggregate products that meet strict customer specifications for shape, size, and gradation. This stage focuses on “finishing” the material, often aiming for sizes ranging from fine gravel down to sand.

Crushers used in tertiary applications are specialized for creating high-value end products. Cone crushers configured for finer settings are common, but vertical shaft impactors (VSIs) are highly prized in this role. VSIs utilize a unique “rock-on-rock” crushing action that fractures stone along its natural cleavage lines, resulting in an excellently shaped, cubical product with minimal flaky or elongated particles—a critical requirement for high-performance asphalt and concrete mixes. The control available in this stage directly influences the quality and marketability of the final output.

Selecting Equipment Based on Material Properties

Choosing between different types of crushers at any stage depends heavily on specific project requirements rather than simply following a fixed rulebook. Several critical factors guide this selection process:

- Material Hardness and Abrasiveness: Extremely hard and abrasive rocks like granite are best suited for compression-style crushers like jaws and cones.

- Desired Product Shape: For applications where particle shape is critical (e.g., concrete aggregate), impact crushers or well-configured cone crushers are often preferred.

- Feed Size and Required Output: The starting size from the previous stage dictates what type of machine can accept it.

- Production Capacity Needs: Different machines have different throughput capabilities.

It’s important to note that many factors influence equipment selection; different requirements lead to different configurations which naturally affect overall investment considerations.

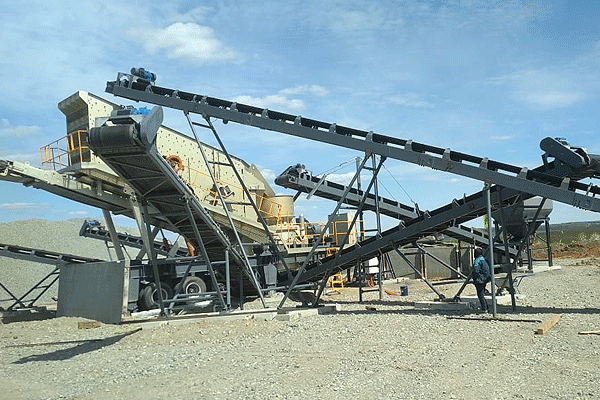

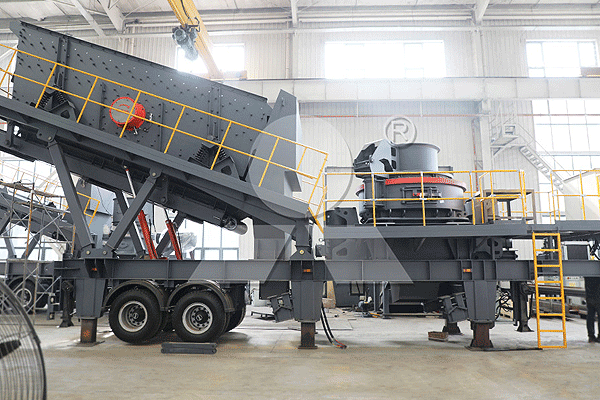

Optimizing Your Crushing Circuit Layout

A well-designed crushing circuit integrates all three stages—primary, secondary, and tertiary—into a seamless flow that maximizes efficiency throughout production lines while minimizing bottlenecks at any point along its path toward achieving desired outputs efficiently without unnecessary re-circulation or energy expenditure within each step involved during processing cycles themselves! Proper planning ensures smooth material transfer between stages using conveyors while incorporating screening decks allows properly sized materials bypass further unnecessary reductions saving power wear costs significantly over time thus boosting profitability substantially long term basis operations run smoothly day after day year upon year reliably consistently meeting demands placed upon them effectively efficiently possible only through thoughtful design implementation right from start project lifecycle onwards always keeping end goal sight throughout entire process development execution phases alike ultimately leading successful outcome overall venture undertaken by stakeholders involved project’s success paramount importance everyone concerned parties alike all around world today’s competitive marketplace environment globally speaking now more than ever before history mankind’s industrial evolution thus far recorded annals time itself!