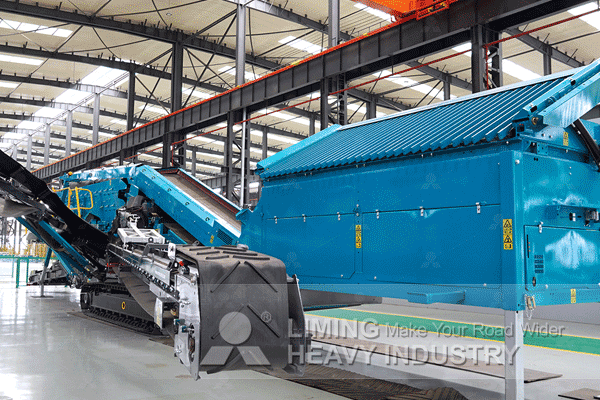

Title: The Ideal Mobile Crusher Plant for Andesite Crushing

Industry Background

The construction and mining industries are growing rapidly. Demand for durable building materials is high. Andesite is a popular volcanic rock. It is hard and tough. It is used in construction and road building. Crushing andesite requires robust equipment. Mobile crusher plants offer a flexible solution. They are efficient and reduce operational costs.

Key Factors for Choosing a Crusher

Selecting the right crusher is critical. Consider the hardness and abrasiveness of andesite. The required final product size matters. Production capacity needs are important. Mobility and setup time are key factors.

| Feature | Importance for Andesite |

|---|---|

| Crushing Principle | Must handle high compressive strength. |

| Rotor/Wear Parts | Needs high resistance to abrasion. |

| Power & Capacity | Must be high to process tough rock efficiently. |

| Mobility | Essential for moving between sites or along a quarry face. |

Ideal Mobile Crusher Type: Impact Crusher

A mobile impact crusher is often the best choice for andesite.

- High Reduction Ratio: It can break large andesite rocks into smaller pieces in one stage.

- Excellent Cubical Shape: It produces well-shaped, cubic end products ideal for concrete and asphalt.

- Adaptability: Impact crushers handle variations in feed material well.

The mobile configuration adds significant advantages.

- Quick Setup: You can start crushing quickly on a new site.

- On-Site Crushing: It eliminates transport costs of raw material.

- Flexibility: Easily move the plant along a quarry face or between projects.

Technical Specifications to Look For

Choose a plant with these features:

- Powerful Engine: Ensures consistent performance under heavy load.

- Hydraulic Adjustment: Allows quick changes to product size.

- High-Capacity Hopper: Reduces feeding frequency.

- Robust Main Conveyor: Handles the heavy, sharp crushed rock.

- Wear Protection: Advanced wear parts in the crushing chamber are essential.

Market Trends & Application

The trend is towards smarter, more efficient plants.

- Hybrid Drives: Diesel-electric systems save fuel and reduce noise.

- Remote Monitoring: Allows operators to manage the plant from a distance.

- Automation Systems: Ensure consistent product quality and optimize production.

Andesite is primarily used in:

- Road base and subbase

- Concrete aggregate

- Asphalt aggregate

- Railway ballast

- Landscaping and erosion control

Future Outlook

Mobile crushing technology will continue to evolve.

We will see more automation and data-driven operation.

Sustainability will be a major focus through better fuel efficiency and noise reduction.

Hybrid and fully electric mobile plants will become more common.

Frequently Asked Questions (FAQ)

Q: Why is an impact crusher preferred for andesite?

A: It delivers a high reduction ratio and produces a well-shaped, cubic product ideal for construction uses.

Q: Can a jaw crusher be used for andesite?

A: Yes, a mobile jaw crusher is good for primary crushing of tough andesite. It is often used in combination with a secondary cone or impact crusher.

Q: How important are wear parts?

A: Extremely important. Andesite is abrasive. Using high-quality, durable wear parts reduces downtime and maintenance costs.

Q: What is the typical lead time for such a plant?

A: Lead times vary by manufacturer and model. It typically ranges from 8 to 16 weeks after order confirmation.

Case Study

A large infrastructure project in Southeast Asia needed to process local andesite for road construction.

The main challenge was the rock’s high abrasiveness, which caused rapid wear on their old equipment, leading to excessive downtime.

The solution was deploying a modern tracked mobile impact crusher equipped with special alloy wear parts designed for abrasive materials.

The outcome was impressive:

- Production capacity increased by over 30%.

- Downtime for wear part replacement was reduced by 60%.

- The excellent product shape improved the quality of the asphalt mix.

[Contact Us Today for a Custom Quote]