Choosing the Right Crusher for Recycling and Rock Applications

Selecting the ideal crusher for recycling or rock processing depends on material type, desired output size, and operational efficiency. Below is a breakdown of key crusher types suited for these tasks.

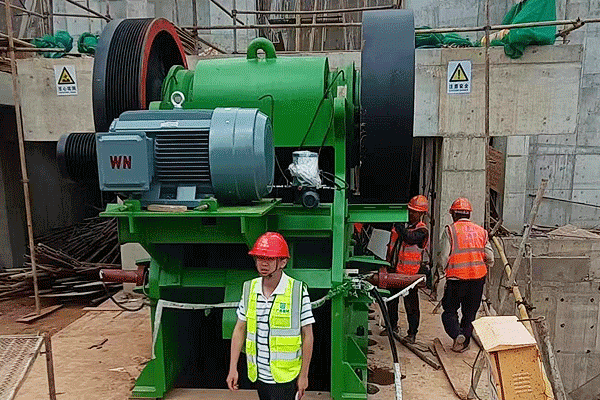

1. Jaw Crushers: Versatile Primary Crushing

Jaw crushers excel as primary crushers for hard rock and demolition debris. Their simple design features two vertical jaws—one fixed and one moving—that compress materials into smaller fragments. These machines handle large feed sizes efficiently, making them ideal for initial reduction stages in recycling concrete, bricks, or natural stone.

Advantages include high throughput and low maintenance, though they produce coarse output. For finer results, secondary crushing may be required.

2. Impact Crushers: Ideal for Recycling Soft Materials

Impact crushers use hammers or blow bars to strike materials, breaking them via kinetic energy. They’re particularly effective for recycling asphalt, glass, or lightweight construction waste due to their ability to produce uniform, cubical-shaped particles.

These crushers offer adjustable settings for output size control but may wear faster when processing abrasive rock. Modern designs incorporate advanced wear-resistant materials to extend longevity.

3. Cone Crushers: Precision in Hard Rock Crushing

Cone crushers are optimal for secondary or tertiary crushing of hard rocks like granite or basalt. They operate by compressing material between a rotating mantle and stationary concave liner, producing finely graded aggregates ideal for construction or road base.

While less suited for mixed debris recycling, their precision makes them indispensable in quarrying operations requiring consistent particle shapes and sizes. Hydraulic systems allow real-time adjustments during operation.

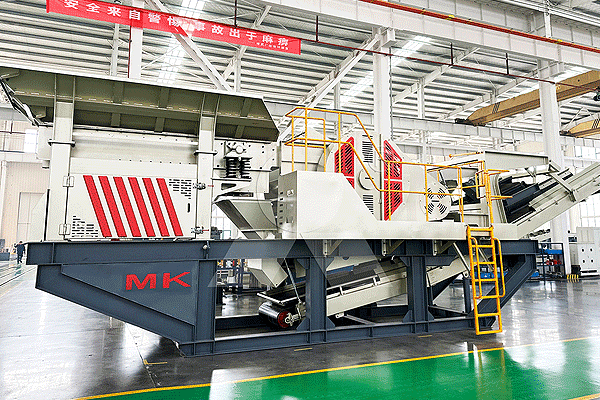

4. Mobile Crushers: Flexibility On-Site

Mobile crushers combine jaw, impact, or cone mechanisms onto a single tracked or wheeled chassis. This portability benefits recycling projects at demolition sites or remote rock quarries by eliminating transportation costs for raw materials.

Key advantages include quick setup and compact footprints; however, they may sacrifice some capacity compared to stationary units due to size constraints. Battery-electric models are emerging as eco-friendly alternatives in urban areas with noise restrictions.

5.Roller Crushers:Efficient Fine Grinding

Roller crushers utilize twin rotating cylinders to crush brittle materials like coal,salt,and certain ores.They apply compressive force while minimizing dust production,making them suitablefor mineral processingor recycling glass/ceramics.

Their gentle crushing action preserves material integrity but isn’t recommendedfor extremely hard rocks.Design variations include single-roll(double roll)and hybrid models balancing speedand fineness.

Conclusion:The Best Fit Depends on Your Needs

No single crusher suits all scenarios.For primary rock reduction,jawor gyratory models dominate.Recycling softdemolition waste?Prioritize impactors.Mobile units add versatility,and cone/roller systems refineoutputs.Consult specificationslike feed size,wear resistance,and mobilityto match your project’s demands efficientlywhile minimizing downtimeand operational costs